Depending on the driving style of the owner, manual transmission clutches can be subjected to a lot of abuse. An owner can wear the disc linings out in just a few days or even within hours. How quickly the clutch pedal is released determines how long the clutch disc will last. Those with a tendency to let the clutch out slowly or leave slight pressure on the clutch pedal clutch disc will experience rapid clutch wear. Living in mountainous areas also works the clutch assembly harder, as owners are fighting the forces of gravity when attempting to roll away from a stop going uphill.

Choosing the correct clutch assembly is important for long life and driving ease. This is especially true if plans are made to increase power or frequent the local drag strips (road racing or Gymkhana events are not as rough on the clutch assembly).

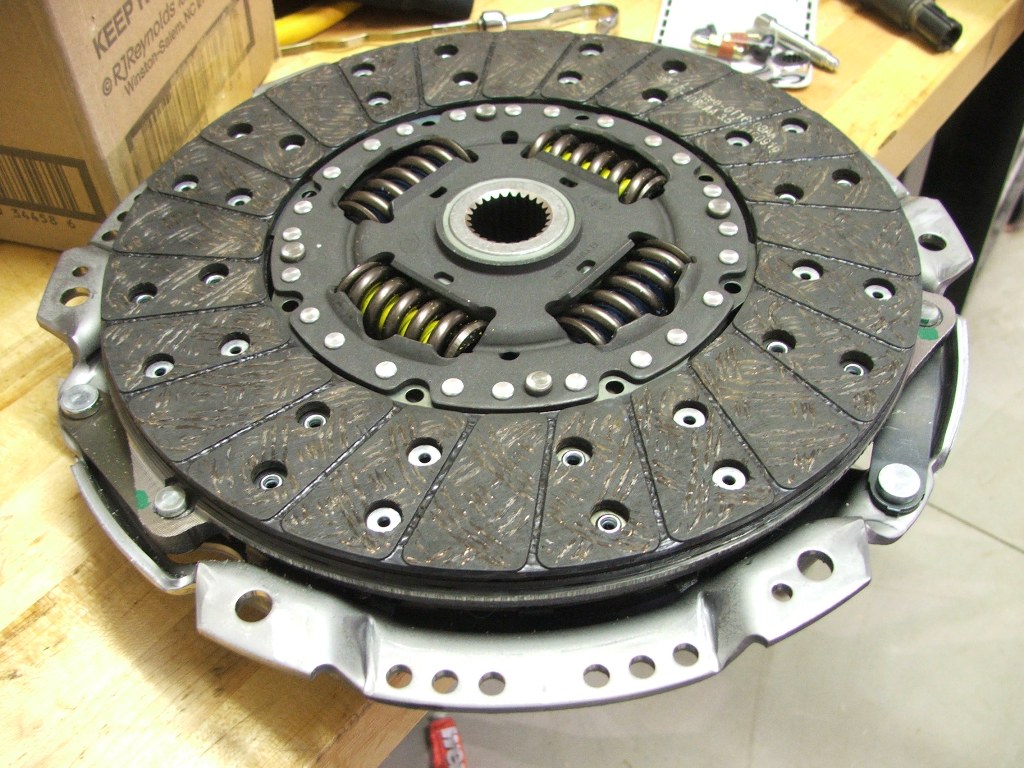

The clutch disc uses a metallic center plate with a complex friction material bonded to it. Rivets are used to bond the friction material to the metallic disc. Clutch discs have dampening springs in the center, sandwiched between the outer plate and inner hub. The dampening springs allow the outer plate lined with friction material to rotate slightly on the inner hub during engagement. The inner hub is splined to the transmission’s input main shaft, propelling a Corvette down the road. The dampening springs absorb the shock of the torque loading as the clutch fully engages. Matching the correct dampening springs and friction material to vehicle usage is very important to allow smooth engagement.

Pressure plates are spring-loaded devices that clamp the clutch friction disc to the flywheel. As you can imagine, it takes quite a lot of spring clamping force to propel a 3000-pound vehicle down the road. Pressure plates come in two forms for most automotive uses. GM has used diaphragm pressure plates equipped with a belleville spring (coned metallic disc that can be over-centered using relatively light force) to apply clamping load for C3, C4, C5, and C6 Corvettes. Once they spring back from over-centering, they clamp very well. This diaphragm-style clutch also works well with hydraulic clutches used today.

Borg & Beck three-finger style clutches are commonly used with mechanical clutch linkages. The Borg & Beck pressure plates use coil springs to apply disc clamping force. The three-fingers work similarly, using levers to over-center and disengage the clutch. The downside to Borg & Beck clutches is effort. Their design takes more pedal effort for the same clamping force as the diaphragm clutch. Because of the additional effort required, the Borg & Beck works better with a mechanical clutch linkage. The upside to the Borg & Beck style clutch is that it will engage at high RPM without fail.

Diaphragm clutches have a tendency to stay disengaged at high RPM, especially if the clutch is out of adjustment. Before there were hydraulic clutches, it was common to find the clutch pedal still on the floor while attempting to shift through the gears at high RPM. We found that adjusting the clutch so that it just barely disengaged helped prevent stuck pedals. Centrifugal force would prevent the belleville spring from over-centering if it went beyond a certain point. Hydraulic clutches will not allow for adjustments, so the clutch manufacturers have had to work their magic to prevent sticking clutch pedals. They have to precisely measure the final clutch stack to limit any excess belleville spring movement.

Buying the Correct Clutch

Clutch manufacturers have to consider many possible scenarios during the design stage. Customers want a clutch that grabs smoothly with the least amount of pedal effort. City traffic and gridlock quickly get old when dealing with high clutch pedal effort. Those who plan on hard launches in their C5 will want to strongly consider a performance clutch assembly. Sticky tires will also need to be figured into the equation. Once you have the variables considered, ask questions. We have plenty of options, from stock replacement to Fidanza and Ram performance clutch assemblies. Remember: aggressive clutches will grab quickly and can chatter depending on how the clutch pedal is released.

Common Clutch Problems

Clutch chatter is usually caused by warped clutch discs and pressure plates or (less likely) oil and grease contamination. To date, we have never witnessed anyone complaining of oil or grease contamination with their C5 or C6. Because of the rear transaxle, there is no way of getting transmission fluid on the clutch assembly.

Slippage is what occurs when engine RPM is increasing on a slight grade, but your Corvette is losing speed. This is usually due to clutch disc friction material loss. High RPM banzai runs can shuck the friction material off instantly. Typical wear from usage is noticed when the clutch pedal is almost fully released before the Corvette starts to move.

Vibration is usually the next symptom of clutch slippage. When big pieces of friction material come off the clutch, disc vibration occurs. In most cases, the Corvette is not able to move under its own power from a slipping clutch disc before the vibration is noticed. The clutch is ready to give up the ghost when you notice slippage and then vibration. At that point, the best thing to do is nurse your Corvette home and check into a new clutch assembly.

Gear clashing during shifting can be due to the clutch assembly. When you are shifting through the gears, the input shaft slows down upon clutch disengagement. Input shaft slowdown allows the transmission to shift easier, as the upshifted gear ratio is closer in speed to the previous gear. The input shaft can drag for a couple of reasons. Contamination from oil or grease can cause the clutch disc to drag on the flywheel or pressure plate. Pilot bearings can also cause drag if the bearing has gone bad or the lubricant has dried up. As the input shaft drag worsens, shifting into first and reverse can become very difficult.

Replacing the Clutch

Tools needed:

- 8mm socket

- 10mm socket

- 13mm socket

- 15mm socket

- 18mm socket

- 21mm socket

- 24mm socket

- Torx T15 bit

- Torx T30 bit

- Flywheel tool (recommended)

- large C-clamp

- transmission jack (2 recommended)

- jack stands

- Ford A/C and fuel line disconnect tool

- new clutch and flywheel

- remote fluid bleeder

- slave cylinder, Corvette Central part #535050

- 4.1 quarts GM Syncromesh, Corvette Central part #531196

- Blue Loctite

- clutch alignment tool

- (2) 16 oz. bottles of brake fluid

- small vice grips

- flat screwdriver

Torque specifications:

- Slave: 106 inch lbs.

- Flywheel: 15 ft/lbs; 37ft/lbs; 74 ft/lbs with blue Loctite

- Factory pressure plate specifications: 20 ft/lbs; 30 ft/lbs; 50 ft/lbs (aftermarket will differ)

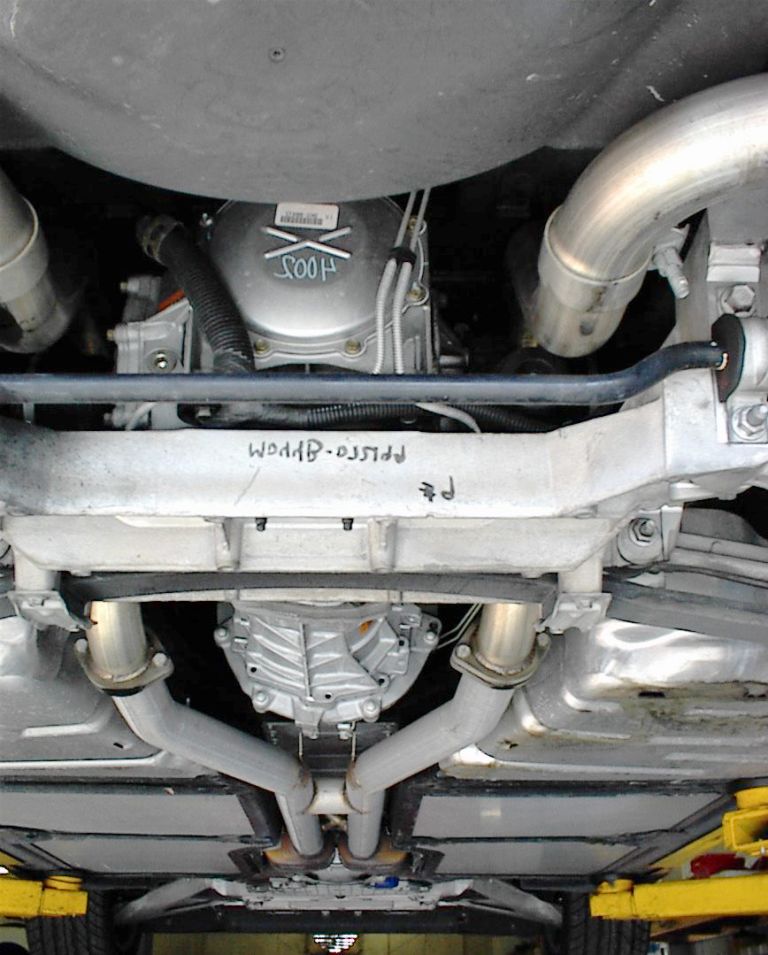

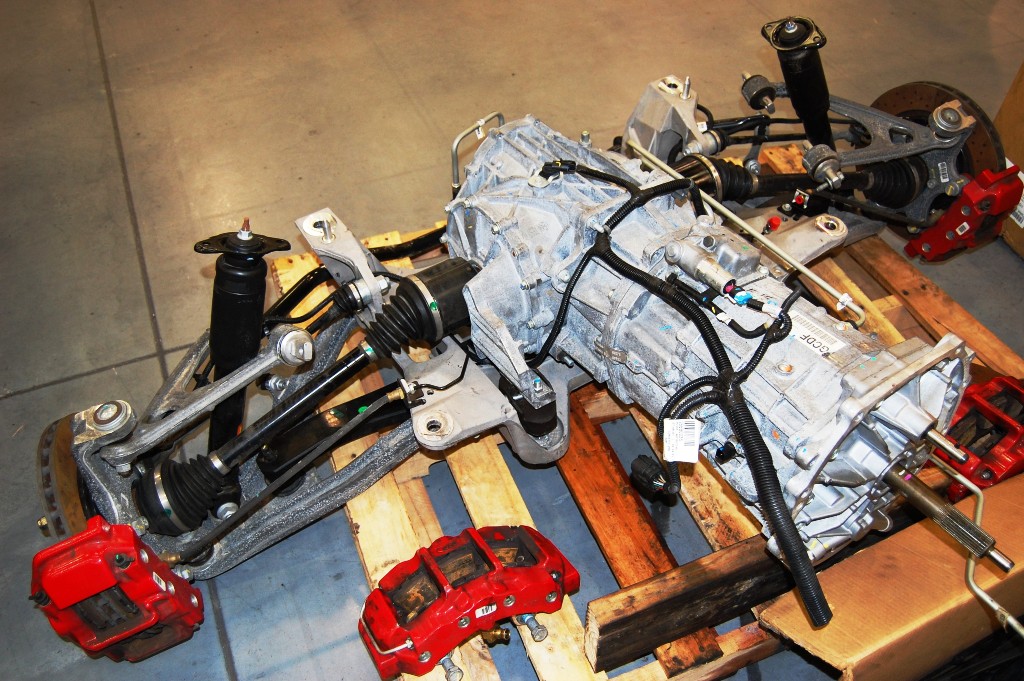

C5 or C6 Corvette clutch replacement may seem daunting. The challenge is pulling the entire driveline (from the torque tube at the bell housing to the differential). The entire assembly comes out of the underside. There are eight bolts that retain the rear upper control arms and shocks to the chassis. Four nuts retain the cradle to the chassis. Once these nuts are removed, the entire assembly will drop (including all suspension pieces with the differential and transmission. Of course, there are a few wires and lines to remove first).

No access to a lift? If you raise the rear of your C5 to the correct height, the differential, transmission, and torque tube can be lowered onto the wheels and rolled back far enough for clutch replacement. Make provisions to get the car at least 2′ in the air. Positioning the jack stands will take some thought, but it is possible to remove the entire assembly in this manner.

The following photos illustrate how the drivetrain is disassembled and reassembled.

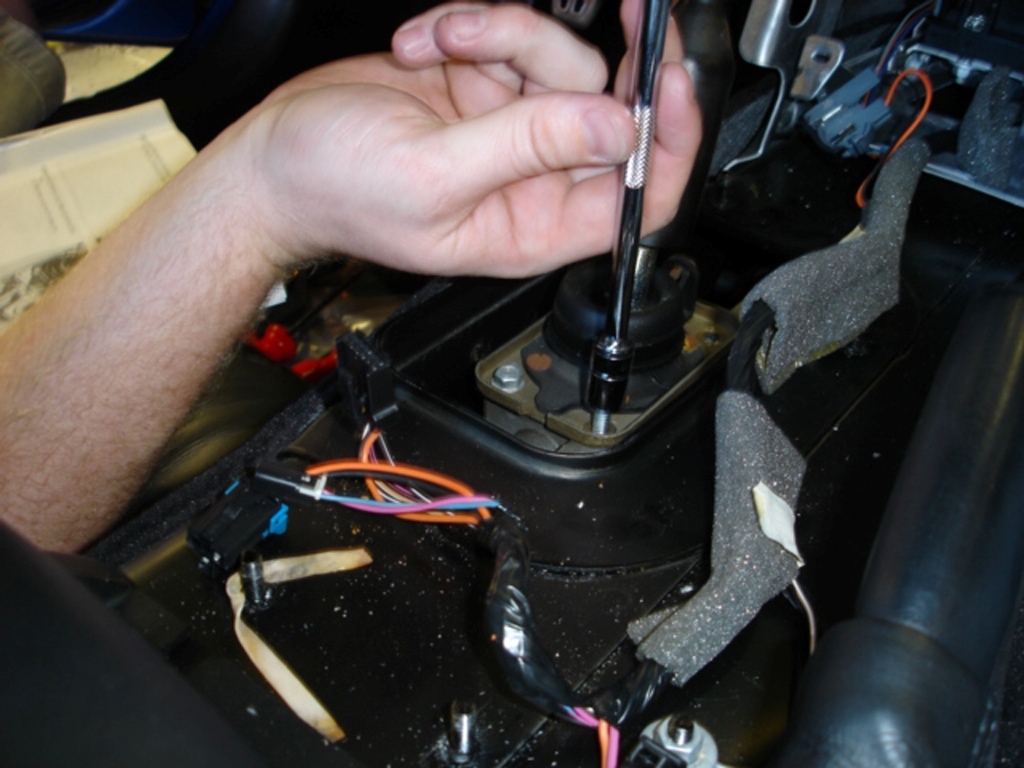

This is where it starts: removing the shifter—the shifter bolts to the torque tube from the top side under the shift boot.

The panel that houses the traction control switch is removed by carefully prying it out of the console. Disconnect the wires and set it all aside.

We remove the console compartment as an assembly. There are screws at the rear under plastic caps that must be removed. Two 10MM nuts are removed from the front, and the console is out of the way.

Pop the a/c inside temperature probe cover off to remove the T15 Torx bit screw holding the center fascia.

Carefully pry the shift emblem out of the shifter knob.

A wedge is used to secure the shifter knob after it is screwed down. The interference fit wedge can be difficult to remove. Wiggling it can help get it loose. Watch that shifter ball leather!

Unscrew the knob counterclockwise.

Remove the center console plate and dash fascia. You will need to disconnect the lighter at the rear of the plate.

Remove the 10MM nuts that retain the shift boot.

Remove the shifter for replacement with an aftermarket assembly (optional). You do not need to remove the four 10MM screws as shown unless you are replacing the shifter.

Remove the rear wheels. Next, remove the rear brake calipers (15mm socket required, two bolts for each caliper). It is always a good idea to tie off the calipers. Do not leave them dangling from the brake hoses.

Remove the two 13mm bolts from the top of the shock (recommended) or from the single 24mm nut and bolt on the bottom. Next, remove the two 18mm bolts from the top of the upper control arm (recommended), or remove the upper ball joint as an alternative. Remove the half shaft from the differential with a pry tool. Disconnect the 2-pin wiring harness located near the emergency brake.

Remove the two 15mm bolts that hold the emergency brake bracket. Proceed to remove the emergency brake cable from the rear of the spindle, and remove the emergency brake cable from the bracket (important: 3 tabs must be pressed. Use a small set of vice grips to hold two tabs in place as you press on the third with a flat screwdriver). Depending on what year you are working with, the anti-lock brake system module wiring must be removed. The rear-wheel speed sensor wiring must be disconnected and moved out of the way. Rear brake lines must be unclipped from their places on the rear cradle. Finally, the four 21MM cradle bolts are removed after making sure everything is supported properly. Repeat this entire procedure for the other side.

Now to the underside to remove the exhaust system.

For muffler removal clearance reasons, the 18MM sway bar nuts are removed from the mounts. Let the sway bar hang. Disconnect the 2 15mm bolts that hold the over-axle pipes to the center pipe. Zip tie through these holes onto a nearby bolt (look for one on the side of the tunnel) to get these out of the way. Pull the center pipe. Note that there are two 13mm bolts hanging from springs near the back. Pay close attention to the O2 sensors. Remove the clips on the sides of the tunnel to prevent stretching the wires.

Remove the 13MM exhaust hanger nuts. Hold onto the muffler as it is ready for removal.

Now is the time to replace that stock exhaust system with one of our Magnaflow exhaust kits. The muffler and exhaust pipe are rolled out over the CV axle shaft.

You need enough room to let the muffler go straight down to get it out completely. A reciprocating saw makes it easy to remove if you decide on a new system. Do not forget about the seals for the front to rear pipes (Corvette Central part number 325123).

These clips hold the rear oxygen sensor harnesses to the tunnel shield. The connectors for the oxygen sensors are up at the front near the exhaust manifolds. While you’re in the area, you can remove the two 15MM horizontal bolts that hold the front pipe assembly to the torque tube.

There are three 15MM nuts on each exhaust manifold connection that must be removed. If you have headers, remove the five 10mm bolts from each header flange and swing them out of position. Hold them in place with straps or bungee cords.

There are also rear exhaust pipe hangers to be removed.

Once the exhaust is out of the way, remove the multitude of 8MM screws holding the center heat shield in place.

Remove the intake tubing from the throttle body before lowering the drivetrain (not pictured). It is recommended to have two transmission jacks to lower the drivetrain. Place one under the rear suspension cradle and one beneath the transmission. Remove the four 21mm bolts for the rear suspension cradle. Note: do NOT use an impact tool for this step, as an impact tool will break the retaining rivets for the nuts (meaning you will have to remove carpeting and cut a hole in the floor pan). To begin removal of the assembly, remove all but two bolts that are used to retain the torque tube to the bell housing. Slowly begin to lower the rear end. You will need to carefully watch for parts to disconnect, like the differential wiring harness. The brake lines will pass between the rear differential and the half shafts. Then the jack is lowered slowly to allow the engine to angle back and stop at the firewall. Do NOT let the engine rest against the firewall, as damage will occur. With the differential supported, have a helper remove the last two torque tubes to bell housing bolts. Move the complete assembly away from the bell housing while the front of the torque tube is held up by your helper. The torque tube is not heavy at this point. Move the assembly out of the way, and be sure to support the torque tube until you’re ready to install the assembly.

Disconnect the fitting leading to the slave (it’s a steel braided line with a big brass cylinder in the middle of it, towards the driver’s side of the car, coming out of the very end of the torque tube near the bell housing). A Ford air conditioning + fuel line coupling disconnect tool is a great time-saving tool for this procedure. Using the 5/8″ version, push in the white (turns to grey if the Corvette has higher mileage) collar on the brass cylinder that is facing towards the front of the car. Once the white collar is completely pushed in, the line will release.

Remove the 13mm bolts at the end of the torque tube to the bell housing. At this point, measure the height of the rear cradle and transmission and/or the jacks. Take a measurement at the front and rear, as the height will vary slightly at each end. This will make it easier when it comes time to reassemble everything. Place a bottle jack underneath the oil pan to keep the engine from tilting upon removing the torque tube. Pull the torque tube and rear assembly backward until the shaft at the end of the tube is clear of the bell housing.

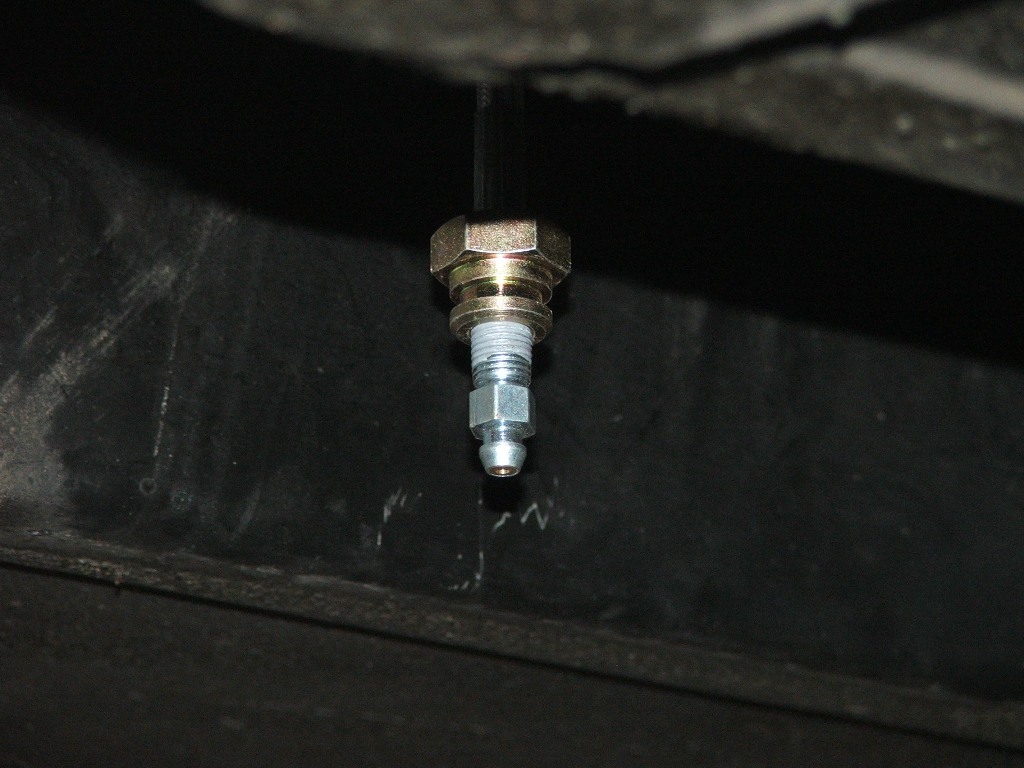

Remove the large wiring harness from the top of the torque tube, in addition to several connectors on the transmission. Completely lower the transmission jacks so that everything will clear upon removal. Observe the shifter base during this step, as it can catch the lines on the driver side of the tunnel. Slow and steady is the key here. Once lowered, position the assembly away from the underside of the car for more space. This is a prime opportunity to replace the slave cylinder (our part number 535050 slave cylinder and release bearing assembly is a direct replacement) and add a remote bleeder extension (pictured is the Tick Performance Speed Bleeder).

The rear cradle allows you to balance the assembly on a transmission jack easier than the differential itself.

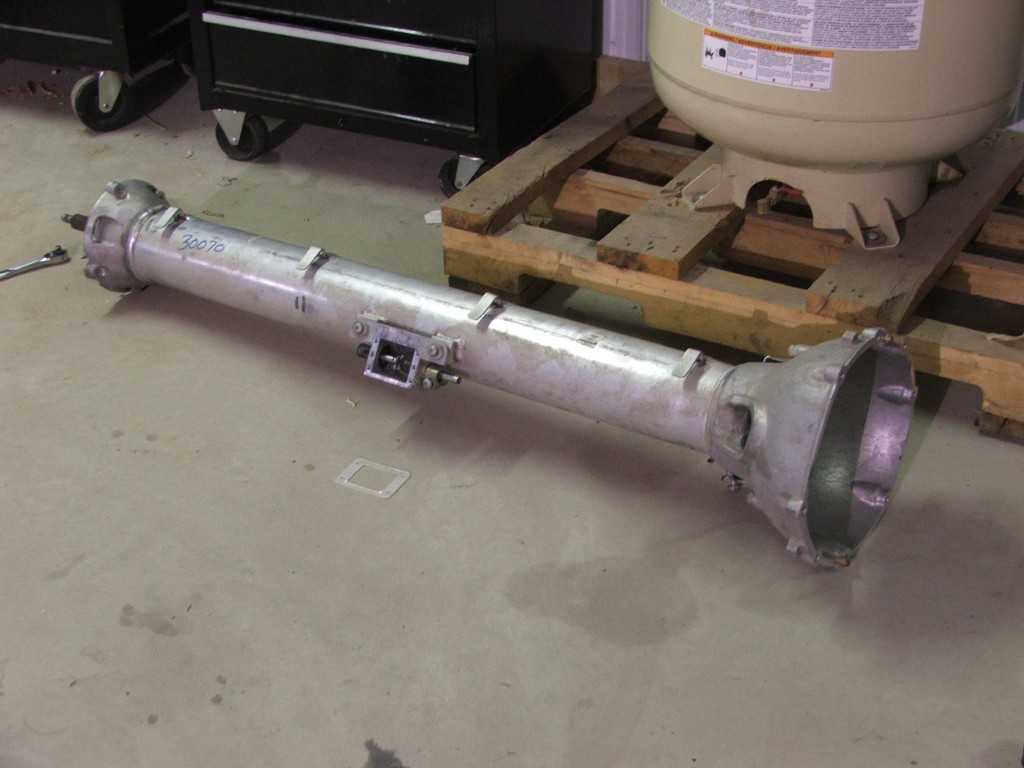

This torque tube photo shows the shifter mounted on the tube with the stick removed. We typically remove the three T30 Torx bit screws and remove the complete shifter. The shifter has two Torx bit screws, and the linkage has one in the rod clamp. For orientation purposes, the left side of the photo is the engine side of the tube. If needed, service the release bearing and hydraulic clutch release cylinder.

If desired, remove the 13mm bolts from the bell housing and pull the bell housing. It is not necessary to do this.

Replacement is like a traditional clutch at this point. Remove the six 13mm pressure plate bolts. The pressure plate bolts should be removed, a couple of turns at a time, in a criss-cross pattern. This evenly releases pressure on the clutch disc and plate. NOTE: the pressure plate and the clutch disc will come out after removing the bolts. Next, remove the 6 15mm flywheel bolts and remove the flywheel.

If the flywheel is checked with hot spots (super hot metal smearing across the flywheel face and then balling up), it should be resurfaced. These hot spots are extremely hard and sometimes will not machine out. The machine tool skips over the hard spot preventing a smooth engagement surface. You should only remove .020 of material from the surface. Something to consider is, has the flywheel been machined in the past?

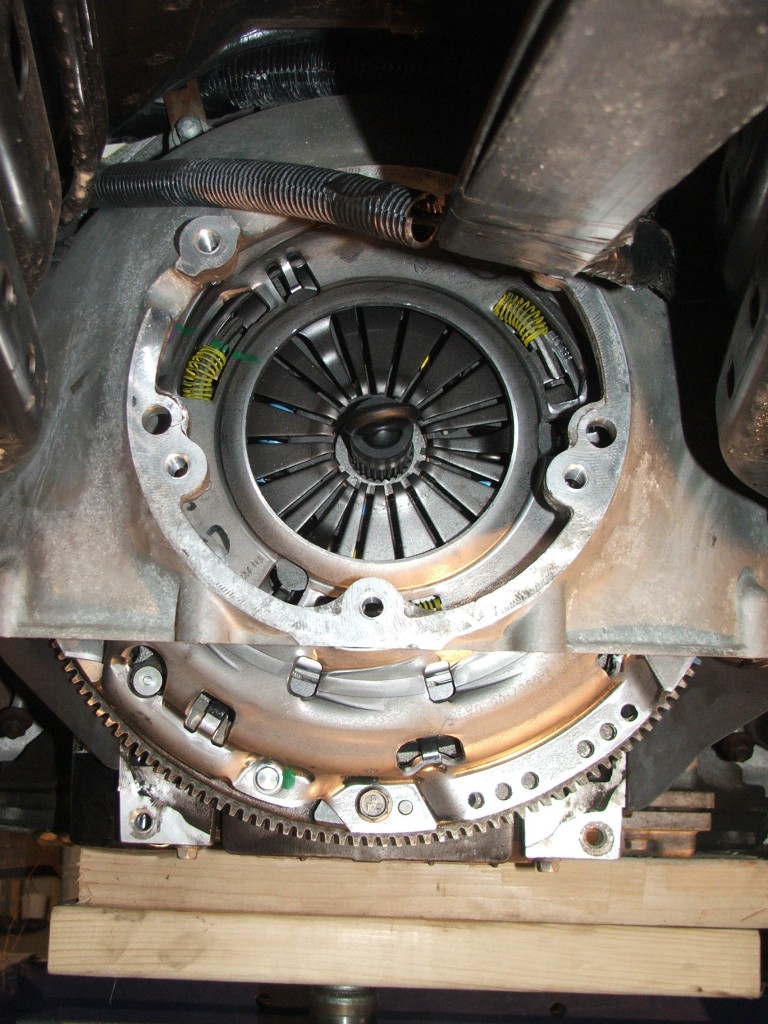

After the main assembly is out of the way, the lower bell housing cover is removed to reveal the clutch assembly. At this point, you can also remove the bell housing to get at the clutch pressure plate bolts easier.

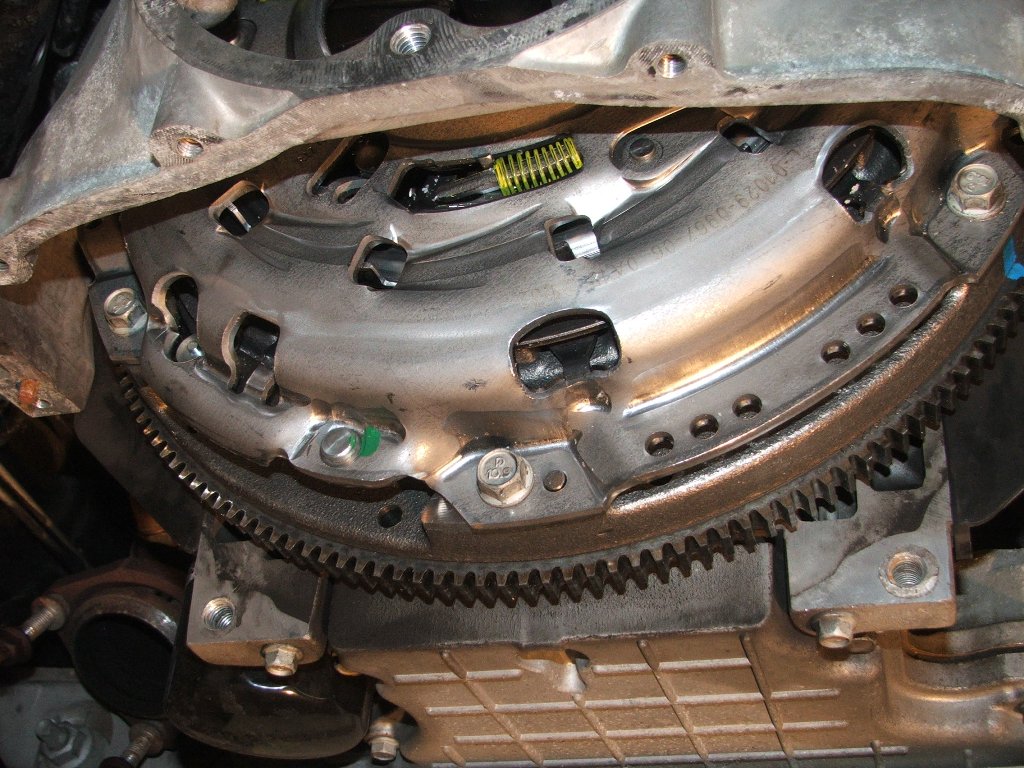

This clutch assembly is from an earlier Corvette. The clutch disc lining has been thrown off from high RPM. The flywheel clutch surface is full of checkmarks (hotspots), questioning the possibility of resurfacing the flywheel. Of course, the pressure plate is junk.

All flywheels have a tendency to cone outward from pressure plate applied forces. Here we are checking to see how bad the cone is with a feeler gauge. Hydraulic clutches have limited travel. Excessive flywheel machining can cause clutch disengagement problems. We use .020 as our maximum allowed machining of the flywheel friction face.

Once the flywheel is torqued and ready for the clutch assembly, wash the machined surfaces with brake cleaner or alcohol. This step is often missed, causing clutch chatter from the contaminated surfaces.

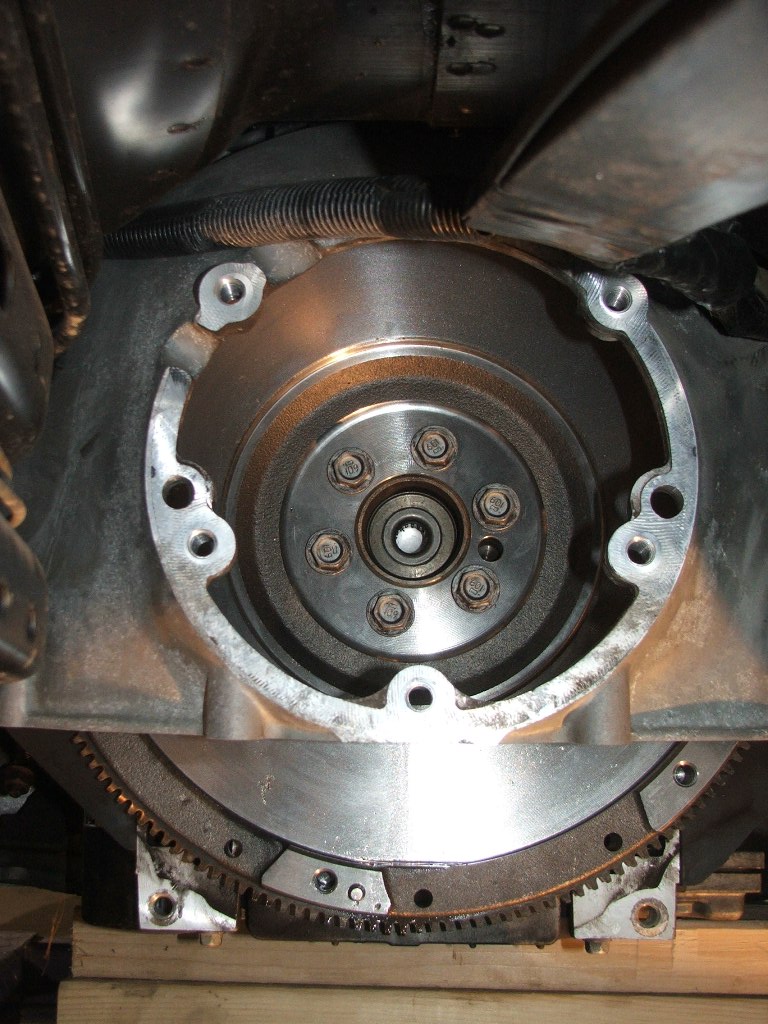

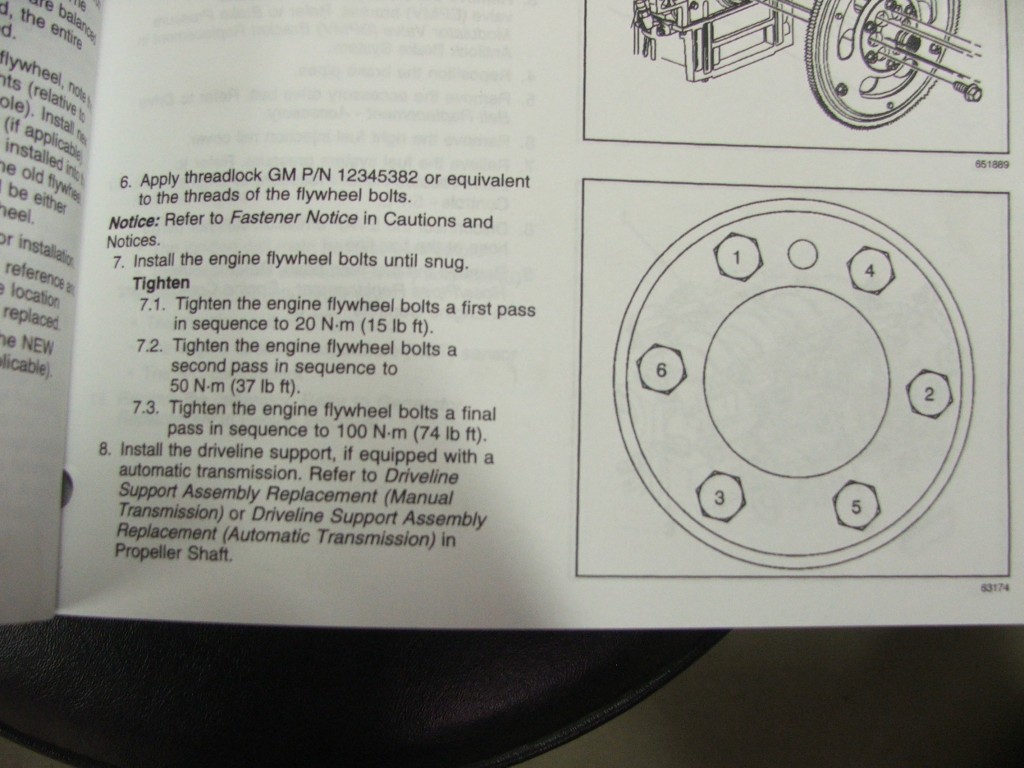

Installing the flywheel takes some care to avoid rear main seal oil leaks from crankshaft hub distortion. Clean the flywheel bolts with brake cleaner and apply blue Loctite to the threads before installation. A torque wrench should be used to incrementally tighten the flywheel to crankshaft bolts in a star pattern. Torque the bolts to 15 lb/ft on the first pass, 37 lb/ft on the second pass, and 74 lb/ft to finish (see above pic).

Put the clutch disc in the pressure plate and place both parts against the flywheel, hand-tighten the six bolts. Find the alignment tool (provided with your new clutch in most cases; if not, an old input shaft will work as a substitute). Position the alignment tool through the pressure plate, the clutch disc, and into the pilot bearing. Tighten the bolts in a criss-cross pattern with 2-3 steps. Note: the factory final torque specification is 50 ft/lbs. NOTE: If an aftermarket clutch is being used, make sure to verify the final torque specs, as they will differ from the factory specs. Failure to do this may result in broken bolts.

When you’re done, the alignment tool should easily slide in and out. Realign if it does not. Tip: hand tighten the bolts, wiggling the alignment tool, then slowly tighten the bolts (give the tool a wiggle every once in a while to check the tension on it).

If needed, service the release bearing and hydraulic clutch release cylinder. Our part number 535050 slave cylinder and release bearing assembly is a direct replacement. The addition of an aftermarket bleeder extension would be ideal here. The throwout bearing is attached via a large spring. To remove the bearing, push it in and rotate it counterclockwise until it pops out.

Now is the best time to replace the transmission fluid. Once the transmission is back in place, a pump must be used to fill the unit. We have part number 531196 GM Synchromesh transmission fluid available for a factory fill. B&M Trick shift fluid is also available for high RPM shifting.

Assembly reinstall

First, completely lower the transmission jacks. Slide the assembly under the car until the tip of the input shaft is positioned near the bell housing opening. Find the height measurements that you took during disassembly. Begin to raise the jacks slowly. Alternate raising each jack, as a single jack cannot support the entire weight of the drivetrain. If available, use a bottle jack at the end of the torque tube to aid in lining up the input shaft with the clutch assembly. Put some lithium grease on the input shaft to prevent squeaks and aid in reassembly. Avoid getting grease on the clutch at all costs.

Once the jacks are at their correct height and the input shaft looks lined up, start pulling, pushing the drivetrain into place. It is strongly recommended to have two people complete this task. It is critical that the splines are correctly lined up. Use a large C-clamp to hold the end of the torque tube and the end of the drivetrain together. Crank the C-clamp down to draw the drivetrain into the clutch.

The input shaft must go through the clutch disc grooves and into the pilot bearing. Keep turning the flywheel in tiny increments until they mesh. The input shaft will slide into position when it is just right. Continue to pull the torque tube and drivetrain closer together. Important: As you get closer, take extra care to ensure that the drivetrain is angled and leveled correctly (use a level on the rear swaybar to verify). After this, use the bell housing bolts to pull the parts together. Take caution not to tighten the bolts before you are certain that everything is aligned; otherwise, you run the risk of cross-threading (and ruining) the bolts in the bell housing.

Reconnect and tighten all connectors and bolts that were separated earlier. Take extra care to ensure that the wiring above the torque tube is not pinched. Also, watch the wiring harness located near the rear mufflers so that they do not touch the exhaust pipe.

Once the assembly is buttoned up, bleed the clutch cylinder, and you’re ready to go enjoy the extra grip from your new clutch. The remote bleeder can be easily zip-tied to the fuel lines to keep it from rattling. We have our part number 534342 GM brake and clutch fluid available for factory fill and bleed.

Story courtesy Chris Petris, Matt Gessler and Dan Baber; photos courtesy Chris Petris, Stephanie Petris and Matt Gessler

very clear and good article easy to understand. Thank you

I had a major rear main seal fail on the road while driving my 2002 c 5. Smoke pouring out from under the hood, engine oil dumped on the roadway. This means removing rear assembly, torque tube, bell housing etc. It makes sense to have a clutch and torque tube rebuild with the rear seal replacement. I have read that the corvette ls1 engine and clutch assembly was “hot balanced” at the factory to prevent drive line vibration, a process not possible in the aftermarket. There are manufactures that do “neutral balance” there clutch assemblies. I was told these are not one in the same processes and I can still have drivetrain vibration. Would appreciate any comments or problems experienced by c 5 owners.

Thank you for doing this write up. Very helpful.

How much is the cost ($$$) of replacing a C-5, C-6 clutch ?

A factory C5/C6 clutch costs between $350-$450

Supposedly the clutch, pressure plate, throwout bearings, and slave clutch were replaced in my 2000 vette not long before I bought it, but it is making a whining noise. Sometimes louder than others, really annoying. What do you think the problem could be? Thanks for all input.

I’d recommend you taking the car to a certified Corvette Technician.

This is a good time to check the couplers in the torque tube, the factory ones start to dry rot after 10yrs or in my case too many hard launches at redline. The clutch job is just a smart thing to do at this point.

Do you have a manual on how to reinstall the shifter linkage? Is there access to it without dropping the transmission and torque tube?

There is a Black tube runs from under the shifter to inside the transmission. This links the shifter to the transmission. Under the shifter there are a few screws that secure the tube. That is the only adjustment.

Should engine rear main oil seal be replaced at this time since access is available?

That’s completely up to you. If there are no signs of leakage then I wouldn’t.

Just wondering why no mention of replacing pilot bearing, especially when they are prone to go bad?