What follows has been reprinted with permission from Corvette Online. Written by Clifton Klaverweiden.

Almost from the very start, the Corvette has been the performance flagship for Chevrolet, showcasing the best in power, handling, and overall performance General Motors has to offer. America’s Sports Car has evolved over the years to incorporate all sorts of new technologies – some, like the C4′s digital dash are best forgotten, while others, like the LS series of modern pushrod small block V8 engines, have shown that even ideas that have been around for a long time still have plenty to offer when given a high-tech makeover.

One piece of technology, the leaf spring, dates back to long before the first automobile, and yet the modern Corvette still makes use of this hardware, albeit in a very interesting and unique way. Is the transverse composite leaf spring suspension found in the C5 and C6 Corvette really holding these cars back, or can it get the job done on the street and at the track? Here, we’ll take a look at late model ‘Vette suspension upgrades from both sides – retaining the leaf springs, or switching to a coilover setup – to help you decide for yourself.

The C5 and C6 are world-class sports cars that can hang with the best of them.

“Leaf” It Alone – Why the Corvette’s Transverse Leafs Work Just Fine

Leaf springs may have been around for a while, but the Corvette’s transverse leaf spring suspension is anything but out dated. Here you can see the rear leaf that spans to both sides of the suspension, and bolts under the lower control arms on Y2K, our project C5 Corvette.

At its most basic, the C5 and C6 Corvette suspension uses upper and lower A-arms suspended by transverse leaf springs made of fiberglass. At first, many people are surprised to find out that a car as technologically advanced, and well known for its handling capabilities as the Corvette actually still uses a suspension design that was first developed for horse-drawn buggies. Leaf springs may not be new technology, but there’s no denying that they can still work very well. If they didn’t, it’s hard to believe that GM would still use them on the Chevy flagship.

This is a shot of the front. You can see the black rectangular leaf spring bolts to the top side of the lower control arms on Y2K.

Two simple mounts bolt the leaf to the suspension in both the front and rear of the C5/C6 Corvette. The compliance in the stock rubber mounting bushings can lead to “crosstalk” that actually sends some of the load from one side to the other during hard cornering.

GM chose to go with the transverse leaf spring design on the Corvette for several reasons. First, the fiberglass composite leaf springs offered a huge weight savings over both coil springs and steel leaf spring systems. When GM first used a transverse composite leaf in the C4 Corvettes that were introduced in 1981, they were able to replace a ten-leaf steel unit that weighed 41 pounds with a single composite leaf that only weighed a paltry 8 pounds. Because the composite leafs have a strength to weigh ratio five times higher than steel, they were able to achieve the same spring rates while shaving off a significant 33 pounds of un-sprung weight from the Corvette.

Here you can see the rear leaf’s orientation to the rest of the suspension. An added benefit of using a transverse leaf is that C5’s and C6’s can fit some pretty huge meats on the rear.Just look how much room there is to spare on Y2K.

The second benefit to the transverse leaf spring suspension design is an increased roll stiffness rate, since the leaf spring somewhat acts as a sway bar (this is both good and bad, but we will get into that later). Since the transverse spring helps to control roll, C5/C6 Corvettes can use slightly smaller and lighter sway bars to achieve the same effect as a huge sway bar and coil springs. Transverse leafs also allow for a lower right height compared to coil springs that have to sit up high in a spring pocket on the frame. Lower ride height means a lower center of gravity and better handling. As an additional benefit, the composite materials used in the Corvette’s leaf springs offer more durability than steel leafs, which have a tendency to sag over time and lose their spring rate.

Without a coil spring running up to the frame, the corvette could be designed around a lower ride height. An added benefit is that the lack of coil spring pockets allows for more cargo room in the back of the Corvette.

These are all great arguments for transverse composite leaf springs on the Corvette, but the real reason why GM put leafs on the Corvette is a simple one: packaging. They just make more sense in fitting to the Corvette’s low and wide chassis. In the front of the car, using the transverse leafs eliminates the need for upper spring pockets, which keeps the hood line as low as possible, improving aerodynamics. In the rear, there simply isn’t room for a traditional coil spring independent suspension, and using a transverse leaf spring helps the late model Corvettes keep all of the rear cargo area they’ve become well known for; meaning you get to put luggage where a spring mount might otherwise be

In the front of the car, its the same story. The lack of coil springs and tall spring pockets means the nose of the car can be kept lower, and consequently have better aerodynamics.

Blair Sonnen, Director of Marketing at Pfadt Race Engineering, had this to say about the stock transverse leaf spring set up in C5/C6 Corvettes: “There is a reason why the leaf suspension has been around as long as it has. Truth is, when its set up properly the results can be just plain awesome. With the leaf springs on the Corvette, you can fit a pretty large tire on the car and get a lot of grip out of it, and grip is what it’s all about.”

So, it seems that transverse composite leafs are a pretty logical choice for use in the late model Corvettes, and there is no denying that they actually work great in about 90% of the driving conditions that the average Corvette will see. But there are admittedly a few issues that can pop up when a C5/C6 is tracked really hard.

Suspension Sass – “Cross-Talk”

The stock transverse leafs work great on the street, but when driven hard on the track, there can be some drawbacks that start to pop up.

The most common issue with the stock transverse leaf springs on a car that gets driven hard is what’s called “Cross-Talk.” This refers to the fact that the Corvette’s suspension isn’t actually 100% independent since the leaf spans to both sides of the car, and connects the two sides much like sway bar. This is when we get back around to how the leaf acting like a sway bar can be a bad thing.

“The term ‘cross talk’ is really a generalized term that refers to one fact: the transverse leaf spring on a Corvettes suspension has characteristics that are similar to an anti-roll bar effect (only promoting roll potentially, in lieu of fighting it) on top of a progressive spring rate. Cross talk happens whenever the car is in roll, meaning whenever it is in a turn and the body starts to roll over the wheels, compressing the suspension. The symptoms are the spring giving a harsh ride and abrupt transitions from a neutral balance or understeer balance, to an oversteer balance, or vice versa.” Sonnen explains.

Sonnen continued by giving us this great example; “Imagine that you have a beam, pivoting upon a single point like a see-saw. For our purposes, imagine it is actually clamped down to the pivot point. When you pull down on one side, the other side naturally wants to move upwards with about the same amount of force.”

“Now take that see-saw scenario and add a second pivot point, again being clamped down say, two feet away from the first pivot point. Now, you are pushing down on one side, which makes the inside of the first pivot point want to be forced upward, which in turn wants to force the outboard side on the second pivot point downward! This is basically what you have going on with the transverse leaf spring system used on the Corvette: the right wheel gets pushed up during compression, and the left wheel gets pushed down.”

Sonnen continues, “The leaf spring reduces the true independence of the suspension, although it is still technically geometrically independent. Using the see-saw example, you can see that any deflection on one side of the leaf, like when you are in a turn and the car’s body starts to roll and compresses the suspension, will have an adverse effect on the other side of the leaf. Adding to the problem is the rising rate in the transverse leaf spring, meaning more force is required to compress it from, say 2-4 inches of bump, than 0-2 inches of bump. This can contribute to a harsh ride characteristic and tendency for abrupt transitions that Corvettes, and especially C6 Z06s, are known for.”

Z06’s actually have a slightly higher spring rate than base model Corvettes, meant to work better on the track.

Suspension Tuning with Leafs

So now that we’ve identified cross-talk as a Corvette suspension tuning problem, how do we get rid of it? Well, that can be a bit of a problem in itself. Cross-talk is just an inherent problem with the design of the transverse leaf springs. But don’t be disheartened just yet. There are still a few suspension options to help you make the most of the stock transverse leaf spring system, and in most cases they can take you as fast around the track as you could ever want to go.

GM Performance T1 Leafs

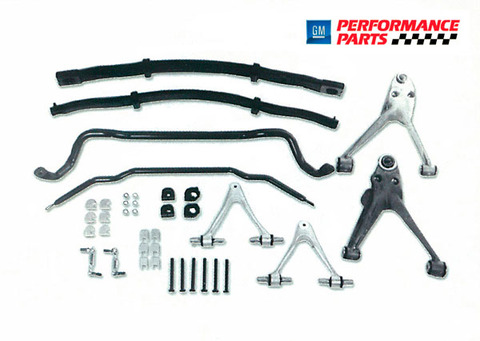

The GM Performance Parts T1 suspension has been used with great success by C5 and C6 race teams in SCCA racing, where the rules require the use of a stock style suspension.

You don’t have to look far to see just how fast C5/C6 Corvettes can be with a stock-style leaf spring suspension. Just look at the success that Corvettes have had in SCCA racing. GM performance actually designed a specific suspension kit for Corvettes racing in SCCA that includes replacement leaf springs with higher spring rates, as well as new sway bars, front control arms, and shocks that is referred to as the T1 Suspension. We were able to speak with Jeff Kettman, a GM Racing Parts Manager about the stock style T1 Suspension kit.

Kettman tells us, “When the T1 kit was first developed for the C5 Corvette back in the late 90′s, the engineer that worked on it came from the Corvette production team and had a lot of knowledge about the production car development and access to the engineers there. Since the primary reason for development of the T1 kit was for SCCA racing and as such, required keeping stock configuration on items like the springs.”

He explains further, “We worked directly with the OEM suppliers and developed custom parts such as higher rate springs. We actually had our own molds made for the springs, but they use the same materials and production processes as the OEM springs, so we get all the quality control that goes into the production parts. We also worked with the production bushing suppliers to make the control arm bushings out of a harder/higher rate rubber. We did go outside to an aftermarket supplier for the anti-roll bars as they were better suited to bend the bigger diameter material necessary to get the rates required for those parts. When it came time to do the C6, we followed the same path and updated the parts as necessary.”

Rebuild it Better than Stock

If you want to keep the stock style suspension, or maybe you are looking for budget minded upgrades, there are still several suppliers that can help you put your C5/C6 in better than stock form; let’s not forget that the first C5’s are nearly 15 years old and some of those suspension components might be getting a little saggy and loose.

If you’re looking to refresh your stock parts, check out Corvette Central, where you can find all the new suspension components you’ll need for a rebuild. It’s also easy to forget that the C5 and C6 can be lowered just by changing the stock leaf spring end attachment bolts. Corvette Central sells 4-corner lowering bolt kit that can help you achieve a lower center of gravity for just $40. Now that’s bang for your buck.

In keeping with the stock-style upgrades, Pfadt offers a few options for guys who want to keep the stock leafs, but still want some adjustability in their suspension. Sonnen tells us, “We offer an adjustable inverted shock that’s a direct replacement. It has better upper and lower mounts and also has an adjustment range for the damping quality. So you could stiffen it up for the track, and soften it up for the street. Since its inverted, that means that the majority of weight is transferred to the chassis, so a bit of the weight is taken off of the control arms, and allows the suspension to react faster to changes. Also, with inverted shocks, you are taking the weight and moving it to the sprung side of the chassis, and any time you can remove unsprung weight, and anytime you can remove weight from the unsprung sections of the car – the wheels, tires, half of the control arms, half of the shock absorbers – it will allow the wheels to react faster, because the less mass you have outboard the better the whole suspension system is going to work.”

He goes on to say, “We also have a line of parts that we developed with long-time Corvette Racing driver,Johnny O’Connell. The Signature Line are OEM quality, million mile warranty, that are literally run on the same production line as the OEM shocks. So you get the same OEM durability, but they have the performance of our re-valving that we developed with Johnny O’Connell.”

Now, hopefully you get the idea that the stock leafs aren’t terrible, and that they actually work very well, so we’re ready to talk about coilovers. Coilovers can have a lot to offer on both street driven and track toy late model Corvettes. “Most of our customers at Pfadt are not building 100% full-race cars, and they want to be able to drive their cars on the street a lot,” Sonnen explains. “Another advantage to coilovers is that there is a tremendous amount to be gained in terms of ride quality because with a truly independent suspension where you can control the spring rates on each corner, you are able to eliminate many of the negative effects of the leaf springs. So with coilovers you can tune your suspension for great streetability and trackability.”

He goes on to say, “The stock suspension is great, but all of the premiere race cars will make the move to a coilover for a reason, and that is to really make the suspension fully independent, and to gain the ability to fine tune the spring rates on all four corners with an almost infinite variety of springs and rates that are available for coilovers.”

The C5/C6 Corvettes actually lend themselves to coilover swaps pretty well. Sonnen tells us, “If a C5/C6 owner is looking at possibly doing a coilover swap from stock leaf springs, it is actually a very straightforward installation. You just remove the stock leaf springs and shocks, and the coilovers bolt in right in place of your stock shocks, and then you just adjust them to your desired ride height. We typically ship our coilovers precalibrated with a ride height that is typically about three quarters of an inch lower than stock, but at the end of the day the right height is totally up to the owner’s discretion. Once you’re done, don’t forget to get the car aligned. A big benefit of coilovers is that they ultimately end up weighing a fair amount less than the stock shocks and leafs that you took off the car.”

Most full coilovers bolt in place of the stock dampers, and completely remove the transverse leafs.

We also talked with Pete Callaway, who you might recognize from the famous Corvette tuning company, Callaway Cars. Callaway developed a different type of coilover system for the Corvette in conjunction with Eibach; the Multi-Pro R2, that actually keeps the stock leafs in place, and adds spring rate through a helper spring mounted to the dampers.

Callaway tells us, ““Personally, we like the stock transverse leaf spring suspension. That’s why with our Multi-Pro R2 we developed with Eibach, we leave the leaf in place and supplement in some spring rate with the coilovers. With our coilovers, we do change the spring rates, but we only do it in small increments; like say 60 to 150 pounds per inch per axle, depending on whether you have a base model or a Z06, since the Z06’s already have slightly higher spring rates. Also, with a supplemental coilover

system like the R2 that keeps the stock spring in place, the vehicle’s weight isn’t just resting on the stock shock towers that weren’t really designed to carry that much load.”

Callaway developed the Multi-Pro R2 coilover system with Eibach to supplement, and not entirely replace the Corvette’s transverse leafs.

He continues, “What we really look for is a change in the damping with these cars. With the R2, we focused on the valving of the damper to tune in the characteristics we wanted it to have. We are looking to add wheel rate without the driver being able to perceive any harshness on the road, and we do that with damping. When you look at the vehicle’s mass, unsprung mass, the balance front to rear, and you can figure out your target spring rates pretty quickly. So really, the character that comes out of a suspension change really comes from the dampers, so that is where we spent most of our development time.”

Leaf it Alone, or Coil Up?

Hopefully through this article you’ve gained an appreciation for just how good the stock suspension on the C5 and C6 Corvettes actually is. It’s a typical case of “bigger isn’t always better” – just because coilovers offer the most performance in the form of a wide range of adjustability, doesn’t necessarily mean that they are the best option for your particular car. As with most other modifications done to your car, you need to first start with deciding exactly how the car will be used, and go from there. If you’re planning to spend the vast majority of your time on the street, then a stock style suspension will likely be enough for you, but if your Corvette will share a significant amount of time between the street and the track, the you might want to look into a set of coilovers so you can have the best of both worlds. It’s totally up to you, and how you plan on using your Corvette.

If my C5 is scraping more frequently than what I believe it use to, could it be the shocks? Granted I have over 260k miles on the car with its original shocks, but there are no signs what so ever that the shocks are not doing their job or worn out. With the exception that the air foils scrape easily and often.

Worn shocks can cause the vehicle to sag, but if they feel stiff and not “floaty” then it can be hard to say. You can inspect your shocks and see how responsive they are when compressed. Unless you believe you have an issue with your shocks, you may want to try adjusting your leaf spring adjuster bolts to raise the car up.

I have a 2003 C5 ZO6, can you run a coilovers on the front and the Leafs on the back thank you Jason

I’d recommend reaching out to a performance or custom alignment/suspension shop for their opinion.

What is the difference between the base C6 spring rate, sway bars, Z51/FE3 suspension and the T1?

Is replacing leafs with coil overs ever known to damage rear mounts on a 2005 c6 corvette? I’ve read that the mounting brackets look too weak to carry the whole weight of the car. Just wondering if it’s a real problem.

WHAT AFTER-MARKET PARTS WILL BEEF UP PERFORMANCE AND HANDLING OF A 2005 CORVETTE.

We carry a huge selection from Mild to Wild performance parts, so it depends on your goals. We offer exhaust kits, camshaft swaps, or you can go all out by bolting on a Supercharger. The article above gives good advice on handling. Feel free to give us a call at 800-345-4122 for more information or specific advice.

C6 z06 front end is sagging. Had to remove front end splitter