If your Corvette was built after 1981, the Check Engine or Service Engine Soon light will illuminate at some point. Unfortunately, there are many misconceptions about the glowing yellow light.

The light illuminates, first and foremost, when there is an exhaust emission concern, low or high charging system voltage, or engine overheating condition. After all, the light is yellow rather than red, which typically means “proceed with caution” unless the engine performance is so compromised your Corvette can’t proceed.

If the Check Engine or SES warning light comes on, glance at the gauges. If the system voltage and coolant temperature appear normal, you should be able to make it home and schedule a service appointment.

Seek help as quickly as possible if the engine is running poorly or you hear spark knock under acceleration. Spark knock is a death sentence to your engine. There are situations when the knock sensors have failed and the system goes into limp home mode, which may cause engine damage if you go a long distance. Flatbed towing is expensive but new engine pieces cost plenty more.

When you stop at a traffic light, you may glance over at the car next to you and notice the SES glowing on the instrument panel. (In many cases, it has been glowing for months.) I imagine those people thinking, “The engine seems to be running okay, so I’ll ignore the light. I see nothing!” However, excessive fuel usage and fuel-contaminated engine oil can result, which causes cumulative damage over the long term. GM programs certain broad parameters that must occur before the SES light is illuminated, so every little variance doesn’t turn the light on. This is usually good for the owner. On the downside, an engine can run somewhat rough and never trigger the light.

As technology progressed, so did the tightening of tolerances for minor emission infractions. It took major problems for the 1981 Corvette Check Engine light to illuminate, while the 1997 would illuminate if the fuel cap was loose. Knowing the glitches that affect certain model year Corvettes helps diagnose the cause of the SES light illumination.

After many years of repairing C4 Corvettes, a distinct pattern emerges. If you investigate and ask the right questions, diagnosis becomes easier. 1984 Corvettes have coolant temperature sensor failures (code 14) 1985-1989s have Exhaust Gas Recirculation (code 32) and Mass Air Flow codes 33-34 quite often. 1990-91 Corvettes had the dreaded code 32. When the 92-96 Corvette was introduced, it had some issues with EGR codes but by far the system was much better and had fewer problems (albeit the 92-94 Opti-Spark ignition distributor woes). Occasionally code 43 was set for knock sensor failure.

Replacing parts is usually straightforward, but knowing what part to replace is the difficult task. Developing sound diagnostic skills can take many years of hands-on experience but once a plan of attack is formulated, finding the root cause of the problem becomes easier. That’s our story: digging deep and finding out what really caused the problem. In many cases, parts are replaced until the problem is solved or masked, causing other issues to crop up.

The first step is to understand the system, through use of a service manual. That doesn’t mean you need to memorize the complete fuel injection and ignition system and how every component works. Just focus on the system pertaining to the code. Factory service manuals have diagnostic trees that prompt you with questions that lead to tests, which will eliminate the possibilities one at a time.

In a perfect world, you would progress through the diagnostic tree, find the culprit and replace it. It just doesn’t happen that way very often. Typically, problems crop up that are not covered in the factory service manual. A prime example is EGR code 32. You go through all the tests and still the code persists. The factory service manual won’t mention that EGR valves have an internal check valve that uses exhaust back pressure to close itself; this in turn permits the vacuum diaphragm to open the EGR valve. Of course the factory doesn’t recommend changing the exhaust system because of the ever-increasing exhaust emission regulations, so there is no reason for them to consider problems that might occur from unapproved modifications or provide diagnostic evaluation info.

Our particular case concerns a poor-performing 1992. The first thing to consider is, were any recent repairs or modifications performed? The owner mentions that a complete cooling system service was performed recently, including draining the engine block. The knock sensors must be removed from both sides of the engine block to drain completely. Afterward, the SES light came on intermittently.

My first thought is possible knock sensor damage which can occur from improper tightening after removing the sensor to drain the block. Knock sensors can also be damaged from dropping or removal if they have been in for many miles. When knock sensors fail, the computer goes into protection mode to preserve the engine if possible. The lack of knock detection turns the cooling fans on at all times and keeps spark advance limited, decreasing performance but you can still limp home.

GM performs many routine system tests at start-up. In the case of the knock sensor, timing is advanced momentarily to see if spark knock occurs. The next question is, does SES illuminate every time at start-up within 5-10 minutes of driving? Our answer is maybe. There seems to be no pattern. Next step is to check the system for codes.

We use GM scan tools and put our Tech 1A to work to interrogate the system. The only code found is not a code that turns on the SES light; it is a QDM code. QDM or “Quad Driver Modules” control ground circuits in high amperage circuits in the computer. GM monitors the circuits to see if, for instance, the cooling fans are working or not. QDM faults affect operation but not emissions, so the SES light is not illuminated even though a code has been set.

I ask the owner if the battery died recently. He confirms it has been charged recently and was giving him trouble.

Before we proceed with the evaluation, the battery needs a full charge and test. While the battery is charging we take a look around. It’s apparent the 1992 has been sitting for a while because the fuel tank is almost full but has that stale fuel odor. We decide to check the knock sensors before starting the engine again.

The knock sensors are screwed into the block drain holes so coolant comes out at rapid rate. If we can leave them alone, we do. We check the knock sensor performance at the computer, which makes the most sense; all the wiring and connections are tested at their final connection points. Tests confirm the knock sensors and wiring are working properly.

With a fully charged battery, we perform a battery test to see if it’s up for the challenge. Unfortunately, it isn’t…plus it’s leaking acid at the side post. We install a new battery so we can road test the 1992 to see if the SES light will come on. We add 104 Octane Boost to liven up the stale fuel beforehand.

Now the best part of the job. We take the ‘92 on a road test, subjecting it to routine conditions to assure that the GM planned software engine system tests are enabled. Moderate acceleration tests are performed during warm-up that enabled the knock sensor performance check, then some steady state cruising at 50+ MPH for oxygen sensor and EGR validation.

Our policy is to accrue 30+ miles on our road test when SES light issues occur and we have no SES light after our 30 plus mile road test. We subsequently allow the ‘92 Corvette to heat soak for 30 minutes afterward and then go on a short 5-6 mile road test to see if the SES light illuminate; still no light.

No reasons are found as to why the SES light came on previously. The most likely cause is a poor connection at the knock sensor or a battery voltage discrepancy. The owner has been driving the car lately with no issues. A few simple checks, battery terminal cleaning, and a battery takes care of what could have been misconstrued as a major issue.

When we refer to the Assembly Line Diagnostic Link (ALDL), this is where it all happens. The ALDL provides serial data from the ECM (Engine Control Module), CCM (Central Control Module), ABS (Anti-lock Brake System) and entertainment system. Although it is very basic, it all starts from here when that SES light illuminates.

Once connected, the Tech 1A interrogates each system. Whether you are using a factory or aftermarket scan tool, there are a few basic rules. Don’t disconnect the scanner from the ALDL while in scan mode. Don’t knock the connector loose if you are getting in and out to check things. Keep the scanners powered up at all times.

Our only code QDM 28 pertains to the radiator cooling fans and the A/C compressor clutch circuit. A quick check under the hood revealed a cooling fan switch was placed in the left cylinder head to turn the radiator cooling fans on at 225 degrees. That explains why the computer noticed the control circuit was grounded by another source, so no worries there. Although the code is set it won’t turn the SES light on and the system won’t be affected.

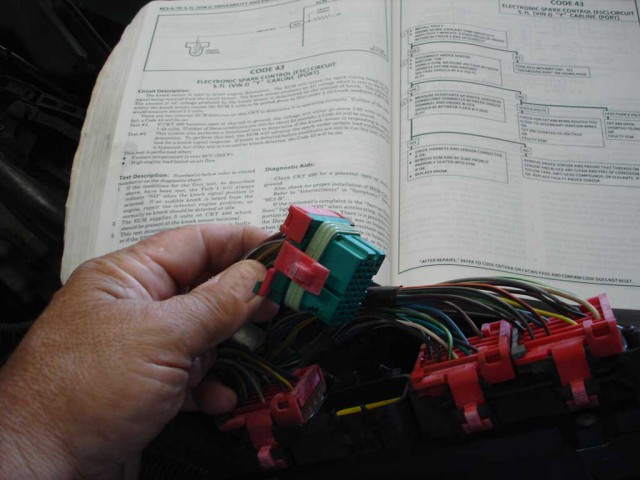

Now that we found out the battery had died and no history codes are stored, we will check out that knock sensor circuit while the battery is charging. First, the computer has to come out of its bracket to access the harness connectors.

The green ECM connector houses the knock sensor dark blue wires. We have our trusty GM service manual to check the knock sensors’ ohm readings. We need to locate the knock sensors’ dark blue wire in position C8 of our green connector. We will check for the proper ohm reading to prove the wiring from the splice to one of the two knock sensors is okay.

We mentioned in the last photo that we proved the wiring was okay from the ECM connector to one of the knock sensors. This photo illustrates how the wiring is in the harness. The knock sensors are spliced together; if one sensor had an open circuit it would not affect the ohm reading because the other sensor is taking the load.

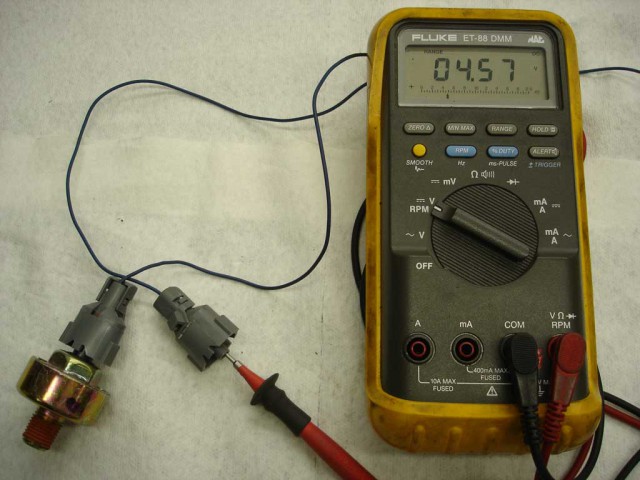

Now we are simulating what voltage you should see when you are checking the harness side of the knock sensor wiring with the key in the “on” position. 5.0 volts is the computer reference voltage that is regulated by the computer and used for all sensor circuits except the oxygen sensor. The reference voltage is dropped to 5.0 precisely controlled volts for accurate sensor readings.

The knock sensor is screwed into the cylinder block near the oil pan rail. Knock sensors, like every computer operating component, rely on a good ground. Knock sensors require just 20ft lbs of torque when tightening. An excess of torque can damage the sensor and that’s why the concern about the recent cooling system service was mentioned.

We should have 3300-4500 ohms of resistance when testing the knock sensor. This new sensor has 3885 ohms nominal resistance. With age, the readings change and knock detection is compromised, so we check the sensors when servicing the cooling system and when performance declines.

This can get you in trouble. The resistance reading is much higher than that of the other knock sensor and the only discerning feature is the plastic connector body is white and the other is black. This knock sensor is for a 1996 Corvette LT4 engine. It’s a major annoyance when trying to figure out the code even though the sensor was replaced.

We always check the throttle body for carbon build-up when customers have performance problems. This particular throttle body didn’t let us down. The throttle bores and throttle plates are full of carbon. As carbon builds up, minimum idle air is reduced, limiting the IAC (Idle Air Control) control valve’s operation. This eventually affects off-idle operation, leading to hesitation and poor idle control at low speeds. A quick wipe out with throttle body cleaner takes care of that pesky carbon.

Another important check is the PCV valve which is often never disturbed until the engine is overhauled. PCV valves have calculated vacuum flow rates that affect air/fuel ratios. Major flow rate changes limit the amount of compensation the ECM can handle. The spring that controls the position of the disc in the valve gets tired after a while, so replace it. They are cheap. If the PCV grommet is hard as a rock replace it also because it can cause a vacuum leak.

Once the battery was charged we noticed a wet side terminal. When we checked we found this lovely corroded terminal. Although the owner had told us he had just recently replaced the battery and cleaned everything up, during the weeks it sat idle the errant acid kept on working on the terminal. A good cleaning and neutralizing with baking soda, then a replacement battery and things were back to normal.

Story and photos courtesy Chris Petris

I have a 1993 40th addition Corvette and purchased with 17,500 miles. After the check engine light came on I checked the ECM codes and the following came up H72, H74, H43. I am addressing the H43 and ordered the ignition spark module. Does anyone know what the H74 code is?

I too had a problem with the check engine light. Code 36 on my 1988. After all systems seems to be doing what they were suppose to do, we narrowed it down to the Mass air plow sensor. After replacing the sensor the light still remained on. Another complete trace we opted to swap out the computer which was a educated guess. Still the same problem? So, the wiring diagram indicated that code 36 (Mass air flow sensor SHOULD not cause this issue.) As a last stitch effort, we swapped out the aftermarket sensor (China!) with an AC/Delco from Rock Auto, and Bang! problem solved. Hope this helps someone with the same code 36 issues.

I have an 88 Corvette service engine soon light on cannot get any codes car runs poor when putting gear is stalls every now and then and a night all the coolant light will come on any suggestions driving me nuts

I too had a problem with the check engine light. Code 36 on my 1988. After all systems seems to be doing what they were suppose to do, we narrowed it down to the Mass air plow sensor. After replacing the sensor the light still remained on. Another complete trace we opted to swap out the computer which was a educated guess. Still the same problem? So, the wiring diagram indicated that code 36 (Mass air flow sensor SHOULD not cause this issue.) As a last stitch effort we try we swapped out the aftermarket sensor (China!) with an AC/Delco from Rock Auto, and Bang! problem solved. Hope this helps someone with the same code 36 issues.

You write:

“Whether you are using a factory or aftermarket scan tool, there are a few basic rules. Don’t disconnect the scanner from the ALDL while in scan mode. Don’t knock the connector loose if you are getting in and out to check things. Keep the scanners powered up at all times.”

Why is that, could the control modules be damaged?

Hi, my 1990 L98 was driving ok, then I parked for a few hours, and no restart,

just instantly fires up at the turn of the ignition key, then immediateldies.

Also I see the SES light in the center of the DIC display is flashing on/off at about

2 second intervals, and under the hood, the purge solenoid relay clicks on and off

in sequence with the SES light.

What on earth can cause this? I tried disconnecting battery terminal, but the fault

does not clear. Any help much appreciated, I am in U.K. (no Chevrolet dealer here).

I recently acquired an 89 base auto with believe it or not 22,580 miles. I guess you could say it was a hell of a barn find.. Anyways I drove it home over 200 miles without a hitch.. It ran and drove like it just came off the showroom floor..

The previous owner a dealership I might add said they had checked all the fluids and had installed a new battery.. After leaving the dealership I stopped to top off the tank for the ride home and double checked the fluids.. Everything looked fine and the ride home was a real joy that’s been years since I’ve experienced.. At 67 yrs old it’s still the greatest feeling to be behind the wheel of another Corvette..

Today I took it out for a little ride and stopped and topped off the tank stopped and ran a few errands and at the last stop when I got back in and started it the SES light came on..

I checked the fuel cap took it off and rescrewed it back on drove for awhile and the light is still on which leads me to believe it wasn’t the cap..

It seems to be running a little rough but very very slightly.. She Accelerates ok but there’s something I can’t put my finger on.. It does seem to be running a little hotter than before it’s highest at a standstill got up to 215* degs and slowly came back upon Accelerating ..

Another problem is the couple of local garages I stopped at didn’t have the old testers to check the codes including both our local Auto Zones.. My tester has long since disappeared unfortunately but that’s what ya get for having gearhead kids.. lol

I’m wondering if anyone can give me some quick suggestions before having to go to the dealer to get it Diagnosed.. Any help would be greatly appreciated

Thanks everyone

The ses light only comes on once in a while but does not come all the time. My code reader says I have a code 13 or O2 sencor. I have a 90 coupe l98 .

I’d recommend taking the car to a certified Corvette technician.

I have a C6 z06 and there is a big noise in the audio system and when i use the computer or using the bose music system (larsen noise) the noise is bigger when the rmp motor increase

I have a 1989 Corvette convertible L98 engine and my SES light came on. I have changed the battery and alternator and noticed the light came on. Should I disconnect the battery? Will this reset and solve the problem or should I get it looked at?

My 89 corvette SES light comes on when vapor pressure builds up in the gas tank. We simply let the vapor out and the light goes off. It may not come back on until a very hot day or a fill up.

I would have somebody take a look at the EGR TEMPERATURE SWITCH. The switch is located in the EGR PIPE in front of the distributor.

You can try disconnecting the battery to see if it does the trick or not. If not id recommend taking the car to a certified Corvette technician.

I have an 88 35 th anniversary with 60k miles. Last year a MAF, IAC, TPS, ICM plugs, wires,coil were put on. Ran wonderful all summer. This year I went to start it and after 30 seconds the SES light came on and it ran light crap like it was going to stall but cleared up in 5-7 seconds no code. It does this every time I use it. If I back it out of the garage and go with it after 3 miles the SES comes on runs bad for 5-7 seconds.. cleArs up no code. I would be more than gracious to pay for advise.. 2 Chevy dealers and a master mechanic can’t figure it out. Thank you