Over time, the original rubber control arm bushings on C4-C6 Corvettes will wear out and fail. While some owners will want to stick with new rubber bushings as a replacement option, there is another option that has become almost second nature in recent years: urethane bushings. These bushings offer two primary benefits: longer life and a firmer, more responsive feel behind the wheel. While this is a task best suited for those with experience and access to a hydraulic press, it can be accomplished with a conventional vise. Follow along as we remove the OEM bushings on a Corvette and replace them with urethane versions.

Using a razor knife to remove the outer lip of the rubber bushing allows it to push out easier. If you do not have a vise or press to push the bushings out, some opt to use a drill bit to cut through the rubber between the bushing and sleeve. Using the razor blade first will also give you an idea of what diameter drill bit to use, care must be taken that you do not drill into the control arms soft aluminum.

This is the easy way, using a sleeve larger than the rubber bushing to receive the bushing as it is pushed out. The hydraulic press does the hard work forcing the rubber bushing out. A vise can also be used in this manner but it takes more effort to get things moving.

Very important to remember: the bolt we are using is smaller in diameter than the sleeve to keep from sticking the push bolt in the rubber. All sleeved bushings can be handled in this manner: C2 through C6 Corvettes.

The rubber bushing is easily coaxed out of the rod end once the sleeve is removed. Kits that do not provide new sleeves will require you to clean up the old sleeve of any rubber remaining on the sleeve.

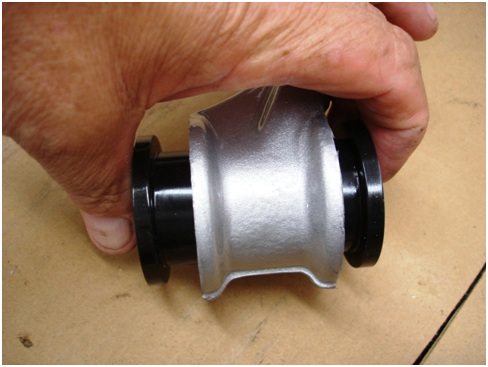

This is the procedure for installing the urethane bushings in the rod end or control arm end. If the machined holes are cleaned properly, each bushing should slide into place with minimal effort. I try to assemble this without grease; the outer portion of the bushing is not designed to rotate in the machined opening. In some cases, you may have to apply just a touch of grease to ease assembly.

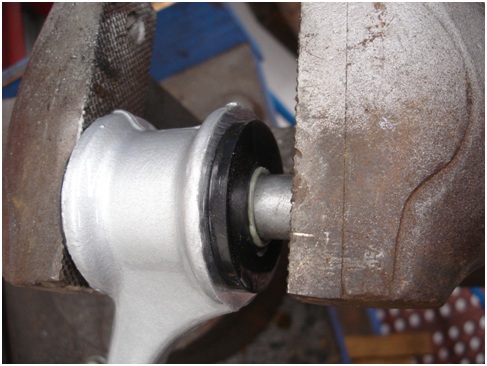

Silicone grease should be applied to the outside of the sleeve and some should also be applied to the bushing’s inner surface. The sleeve should rotate on the bushing’s inner surface; here a bench mounted vise is used to push the sleeve into the bushing halves.

Before installing the control arm or rod end into the pivot point, a coat of silicone will help alleviate squeaking as the bushing pivots. All suspension pivot bolts should be torqued to GM service manual specifications after assembly. Loose bolts cause clunking and or popping noises as you go over bumps.

Story and photos courtesy Chris Petris

On the C6 Corvette the lower control arm bushings are 2 sizes. The larger one has an embedded steel ring that prevents you from placing a socket over the bushing to engage the arm to push the bushing out. the ring must be cut out. Do you know if the back has the same thing?

Nice, tell me how to in Urethane bushings in the upper A arms

Also interested.

Also interested.