If you think about it, your C5 or C6 Corvette door hinges take quite a beating. When open, they’re required to support the entire weight of the door, then take the shock of sudden closure when the door is shut. They do this time after time, year after year, without complaining—for the most part. All […]

How to replace a 1963-1972 Chevrolet Corvette (327 or 350) Radiator

The radiator on my ’63 Split Window Coupe wasn’t doing its job well at all, rendering the car unusable due to overheating after 15 minutes of driving – even less if the ambient temperature was over 80 degrees. While this is a numbers-matching car, the previous owner had made some cosmetic “eye-candy” mods such as […]

Looking for a C5 Corvette Rocking Seat Fix? Here’s a Step-by-step Remedy

If you have a C5 Corvette (1997-2004) with electric seats and some miles on it, by now you’ve undoubtedly noticed that the driver seat (and the passenger seat too, if you usually have someone riding shotgun with you) rocks a bit. In actuality, the seat slides forward during braking and slides rearward during acceleration. This […]

Exploring the 1967-1986 Corvette Tilt/Telescopic Steering Column

Since day one GM has never spared any money in engineering. My co-writer Chuck Schuster and I have been long-time believers in if GM built it that way there was a good reason they built it that way. On the same note, we do not believe GM ever changed anything unless they came up […]

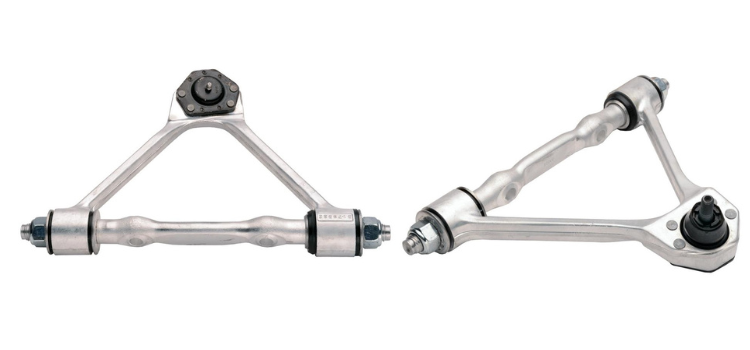

C4 Corvette Upper Ball Joint Replacement

Replacing the ball joints in a C4 isn’t as hard as most people think, although it is a bit time consuming and a complete front-end alignment is required after the installation is complete. The hardest part of this project is the removal of the upper control arms, but once they’re out of the car, the […]

How to Measure Your 1953-1982 Corvette for Proper Tire and Wheel Fitment

1984-2024 CORVETTE WHEEL SIZE & OFFSET CHART Wheel backspacing is a CRUCIAL measurement, if you’re planning to install new tires and wheels on your 1953-1982 Corvette. This measurement determines proper fitment of your tires and wheels and measuring wheel backspacing is very quick and easy. Our beloved C1 and C2 Corvettes feature classic lines and unmatched […]

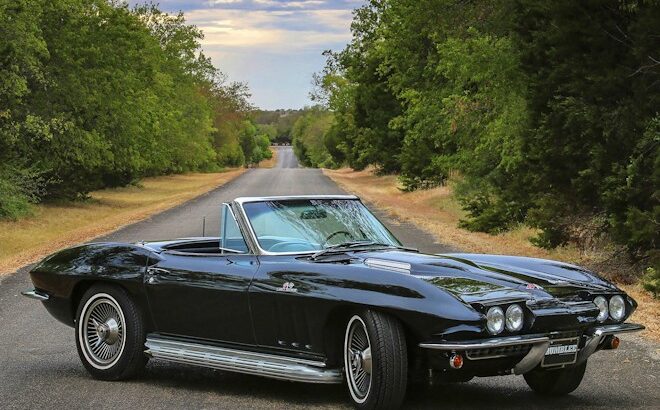

Customer Spotlight: Scott Harrison

Scott Harrison of Texas told us the story of his 1966 427 Corvette, Rumblee Thunder, for this month’s Customer Spotlight. “I’ve wanted a 427 C2 Corvette since I was eight. In 2017, an intense internet search turned up just what I was looking for in western Iowa. A weekend driver was all I was looking […]

C4-C6 Corvette Weather Stripping Replacement

Article and photos by Tom Benford The rubber weather stripping on C4, C5, and C6 Corvette Targa tops eventually becomes dry and fails to seal out rain and moisture the way it was designed to do. When this occurs, the only cure is to replace the weather stripping. In this article, we’ll show you how. […]

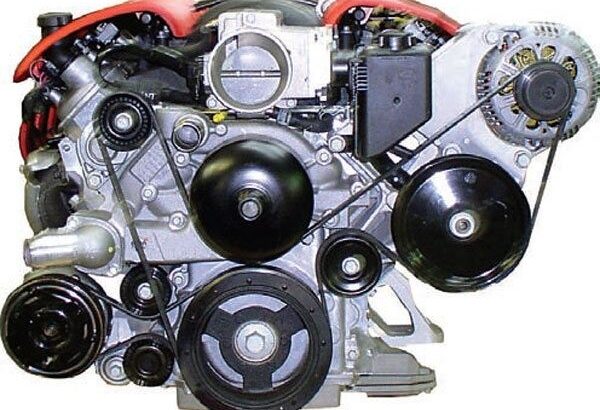

C5/C6 Corvette Serpentine Belt Replacement

Article and photos by Tom Benford Like all things mechanical, the serpentine belt tensioner and idler pulley on your C5 or C6 Corvette engine will eventually wear, develop play, and require replacement. Here’s how to identify when that time comes and how to handle the replacement. When Does a Corvette Serpentine Belt Need to Be […]

Meet the Team: Accounting, Purchasing, and More!

Like any excellent pit crew, we have teams behind the scenes that keep your experience with Corvette Central running smoothly. You might not think about what it takes to keep orders moving, but Corvette Central would be sitting at the pitstop without these teams keeping us going. It all starts with our Purchasing Department. They […]