Original small block “rams horn” exhaust manifolds (produced up to 1979) can be said to flow efficiently. Their flow may not be optimal, but they are better than many of the original equipment manifolds. The idea is to reduce back-pressure while tuning the flowing exhaust gases. The center exhaust ports on the OE cast iron manifolds dump into a rectangular box that the outer cylinder exhaust gases flow into. This mixing of exhaust gases so close to the cylinder head and exhaust valves hurt engine performance from lack of flow.

Long tube headers are most beneficial in consistent high-RPM applications. They also crowd your car’s underside and can pose some ground clearance issues. Once the headers are installed, you need a pipe bender or multiple sections of differing radius pipes to make the connection to the headers. Most of us would end up at an exhaust specialty shop to have them fabricate the required pieces for the installation.

Patriot’s Tight Tuck headers have long radius tubes that are very close to equal length. The long radius tubes promote better individual cylinder exhaust flow while increasing exhaust flow speed at the collector. They certainly look better and require very little maintenance. Shorty headers will not deliver the same performance as full length tuned headers, but not many will be able to feel the performance difference. To sum it up, the tight tuck headers or direct fit big block headers will make your Saturday afternoon easier.

Exhaust work is not one of the more enjoyable car projects. Exhaust systems are usually rusty and bolts are seized and difficult to access. Installing any headers or manifolds that are not factory pieces require cutting and welding. No matter what exhaust work is being done, having a torch nearby is usually mandatory. Corvette Central recognized the struggles with trying to install headers and making the exhaust connection.

Corvette Central Exhaust has been providing complete exhaust systems for many years. Customers can purchase everything they need from one source, from cylinder head to tailpipe. Multiple choices are available: from stock exhaust manifolds and mufflers to headers with performance mufflers.

The exhaust outlets on Tight Tuck headers are inboard slightly from the original exhaust manifold position. The Patriot tight tuck headers will fit GM cylinder heads. Some aftermarket cylinder heads may have fitment issues.

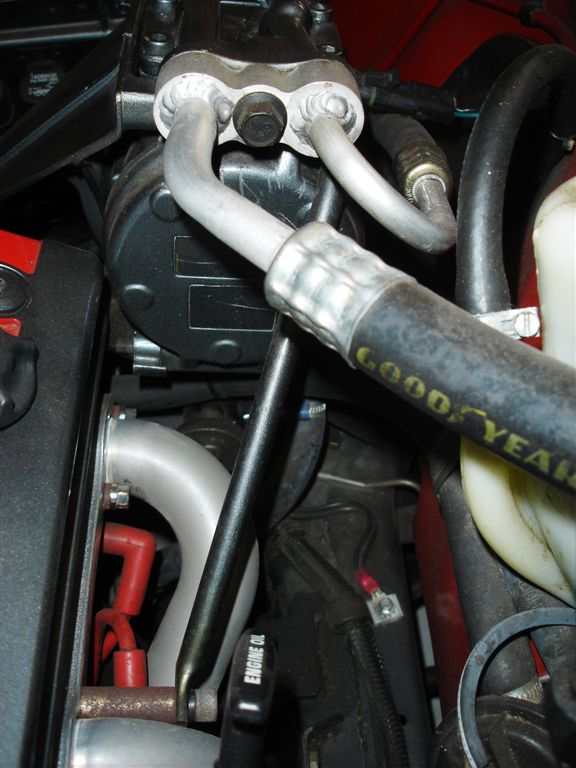

Direct fit big block headers replace the bulky heavy cast iron manifolds, while connecting directly to the existing exhaust system. All original power accessories have adequate clearance. There are no issues with stock type clutch linkage either, as the cross shaft clears without any extra work. Copper coating was used on big block headers to maintain internal header tube temperatures. Small block and big block headers benefit from the addition of durable external ceramic coating. Ceramic coatings have been applied to header tubes to contain heat loss that is associated with the header tubing. When correctly installed, these headers and exhaust system will last a long time.

Corvette Central Exhaust utilizes aluminized exhaust tubing. As the tubing ages, it does get some patina, but it will not rust. The correctly bent exhaust tubing means easy installation with hand tools: no torch and saws required.

We have done some custom work using the Corvette Central Exhaust systems. Using a customer’s 1979 Corvette, we started with the dual exhaust system, adding catalytic converters with our tight tuck flange tubing to the converter. This is an isolated case, but it can be done if you want or need catalytic converters on your later C3.

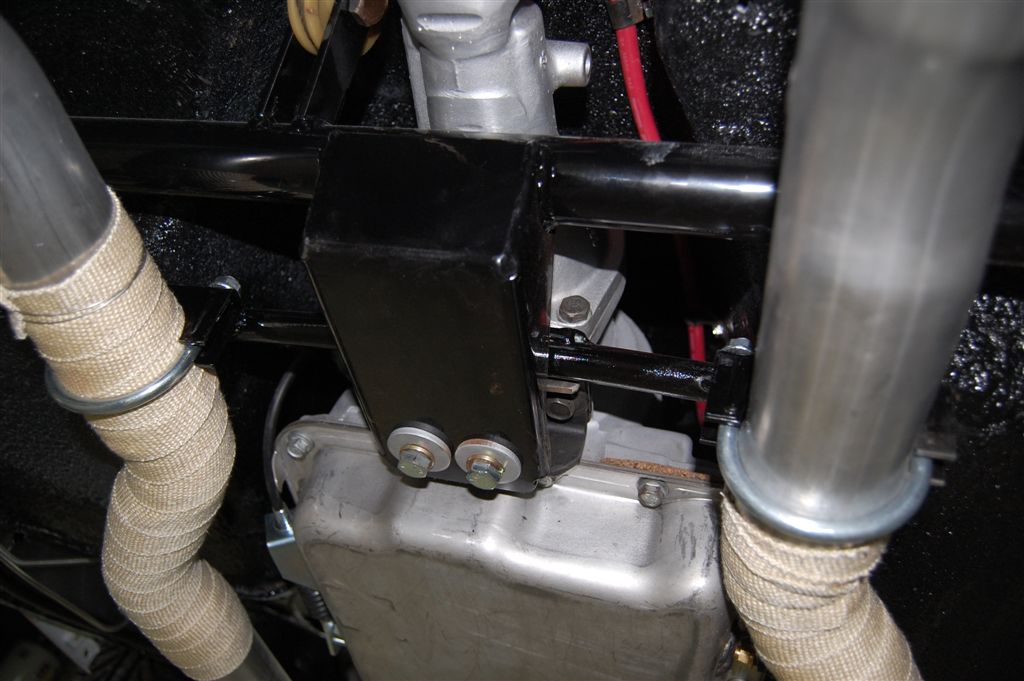

A couple of words concerning exhaust system wrapping: header wrapping materials were used before the ceramic-metallic coating became affordable. The idea is to keep the hot exhaust gases hot, promoting higher flow rates. The problem with wrapping is that it’s installed over painted steel, which ultimately leads to corrosion. The corrosion led to early pipe degradation and failure. Wrapping also prevents the steel tubing from cooling, causing stress failures.

In our shop, we use exhaust wrap products to keep heat out of the engine compartment and cockpit. This is a necessary evil. The better solution would be to coat the pipes in the area where it would help keep the heat away. Not everyone wants to spend extra for the coating on the exhaust system. In these situations, the wrap suffices.

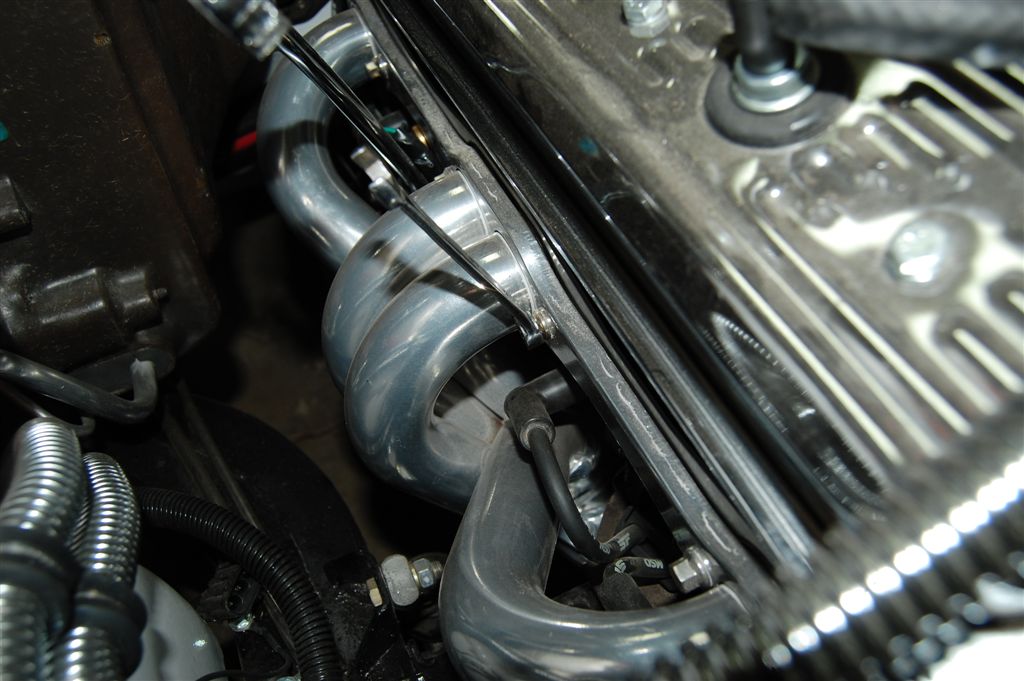

Removing the old stuff was easy. We left it on the original 1977 engine. The Patriot Tight Tuck headers look really good on the crate engine. We are using stainless steel reduced hex head size header bolts for easy socket fit. The 3/8” hex head bolts allow easier installation in the tight spots.

We can even get our 3/8” combination wrench’s box end on all the headers bolts to really get them tight. We are using Earl’s header seals made from compressible graphite to prevent any exhaust leakage concerns. The headers do not come loose when these header seals are used.

Like all Corvettes from 1963-1982, there are no clearance issues with the Patriot headers. Spark plug servicing is not an issue either. You can get to outer plugs as easily as you could with the original manifolds.

This application of the Patriot headers shows some exhaust wrap and a shield in the center. We used a Holley fuel management system that required a knock sensor. The shield and wrap are protecting the knock sensor. We mocked up the header installation before dropping this late model small block into a 1979.

This is the ’79 Corvette after about 30,000 miles. The headers still look good with no corrosion. The only corrosion is on the spacer for the a/c compressor brace. These braces are important when the accessories are hanging out so far from the crankshaft centerline. They stiffen the accessory brackets and quell harmonic vibrations.

Our Corvette Central OE fit exhaust pipe fits without any concerns on the Patriot headers. We used the original length spark plug wires with shielding to keep the heat off the wires. There was no problem fitting the shielding either. It bolted into place without any extra work.

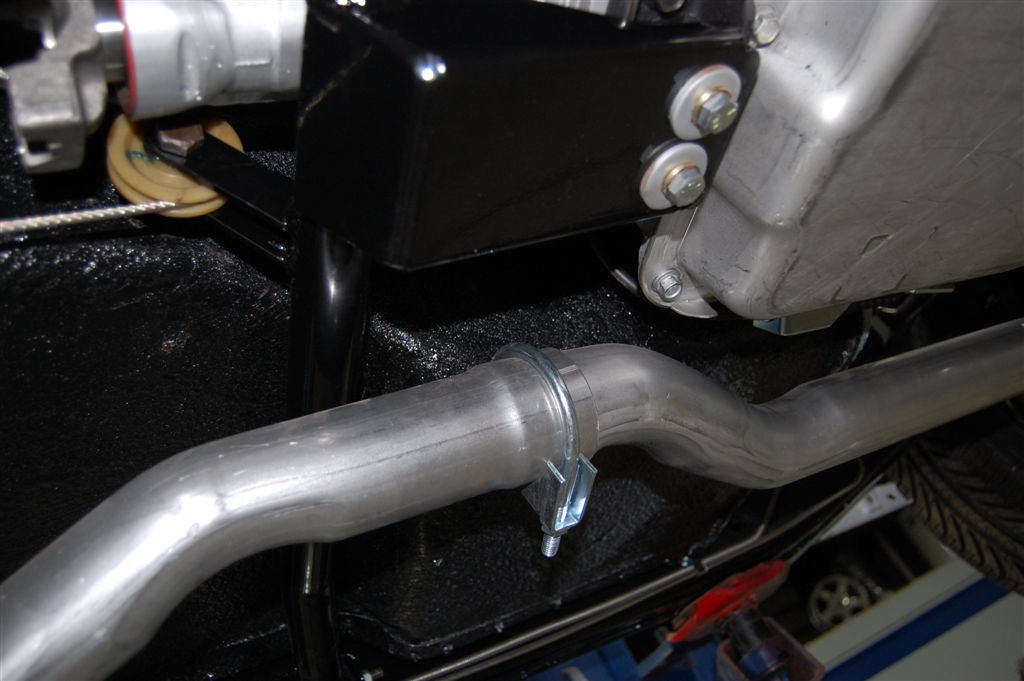

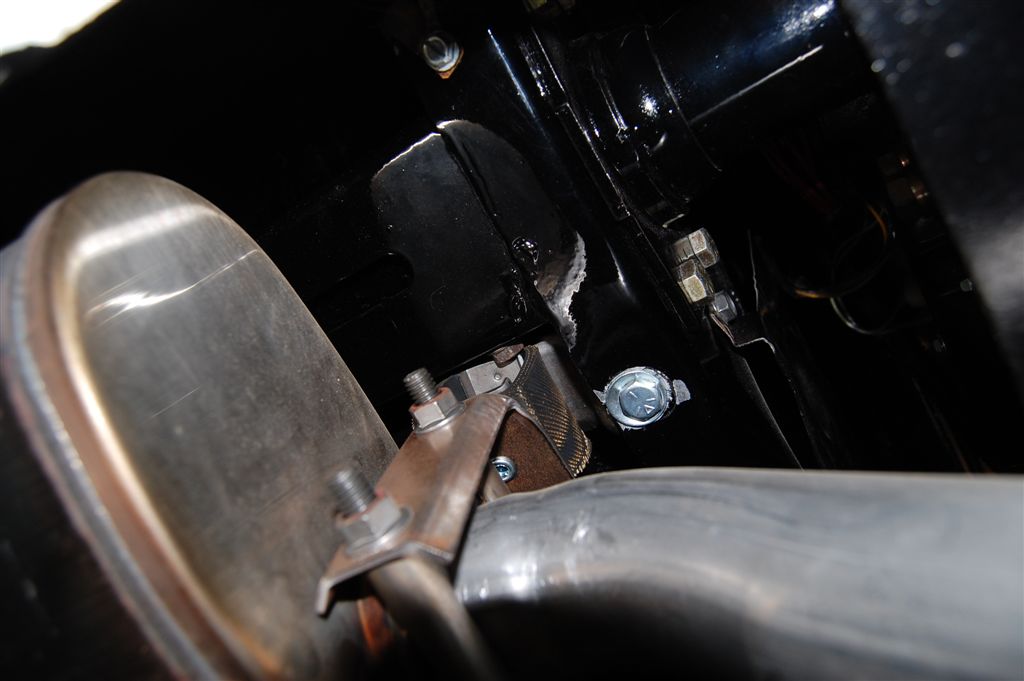

Corvette Central Exhaust places the same slip connection points in locations the factory used. We used the supplied exhaust clamps for pipe fitment. We put enough pressure on the clamp to hold things in place while we went on with the rear pipe and muffler installation.

We installed a 700R4 automatic overdrive transmission in this 1977, using a Bowtie Overdrives crossmember. This crossmember provides flexibility in exhaust placement. We could still use the original crossmember with the Corvette Central pipes if we chose to do so. We wrapped the front pipes to keep cockpit heat down.

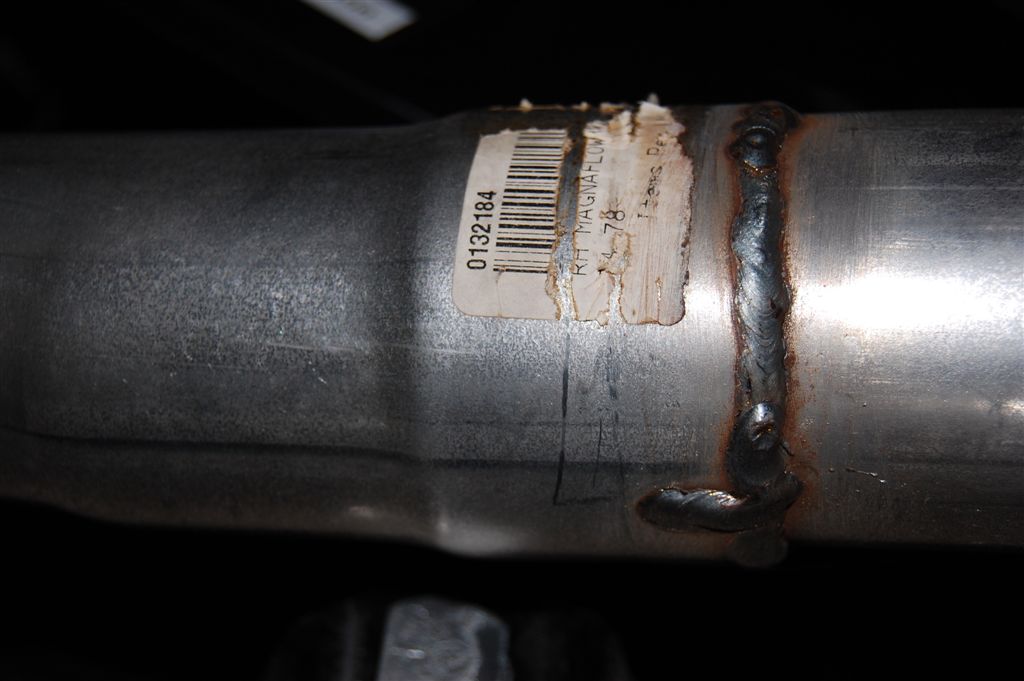

The Corvette Central supplied Magnaflow mufflers are slipped onto the rear exhaust pipes. Corvette Central also has factory look and fit mufflers, if you prefer. Hideaway mufflers are available for 1973-1978 Corvettes to keep the mufflers up where they belong “out of sight”.

Exhaust clamp positioning is something to pay careful attention to. You don’t want the clamps to scrape the spring or catch something you pass over while out cruising. One gouge in the fiberglass spring we are using will cause it to fail, so be careful working around it. The clamps also look better from the bottom when they are turned up with the studs facing upward.

We choose to weld all of our joints with a wire feed MIG welder. We ground the pipes at the very edge to remove the aluminized coating before welding. Try to avoid removing any extra aluminized coating to keep the joint from rusting.

Our Corvette Central supplied rear hangers finish off this install. These correct fit hangers allow adjustment as required and provide vibration-free exhaust support. All the correct fasteners were provided to ease installation.

We added chrome tips on this 1979 to “bling” the back end a bit. We chose the welded installation. Corvette Central also offers the tips with screws for quick installation, if you prefer.

Our 1979 installation with catalytic converters was custom fitted to the Corvette Central complete dual exhaust kit. We were able to use the front exhaust pipes, fitting the catalytic converters in the pipe itself. We used Random Technology catalytic converters and welded a heat shield on the top side of them to keep heat out of the cockpit. The wrap was used for the same reason, keeping heat out of the engine compartment and cockpit.

This gives you an idea how nice the exhaust system fits under the 1977 Corvette. All the pipes and mufflers were fitted and we were waiting on hanger installation. Notice how the Magnaflow mufflers fit up in the fender area, keeping them out of sight once the Corvette is sitting on the ground.

Story and photos courtesy Chris Petris

I really like your exhaust you installed. I own a 1976 Corvette and looking at doing this to my car. The only challenge is that I put aftermarket heads on with angled spark plugs. I’m not sure what headers will work. I was wondering if you had any recommendations? I would like to stay with tight tuck headers. Thanks

I have a 1968 Corvette with 350CI and Edelbrock aluminum performer heads. Will these headers fit the ports which are round with straight plugs?