Time: 3 Hours

Tools: 3/8” drive Metric sockets, box end and flare nut wrenches, GM hydraulic clutch fluid and vinyl hose.

Talent: (3)

Applicable Years: 1984 to 1996

Tab: $150

Tip: Replace both the master and slave units at the same time

When the 1984 Corvette was introduced it used a totally different system for working the clutch. Previously the Corvette had used a series of rods and pivots to connect the clutch to the clutch pedal. Suddenly the Corvette had a hydraulic system. Nothing really new here since this hydraulic clutch actuation system had been used on other cars for a long time.

The Corvette engineering team felt that the engagement of the clutch was much smoother with a hydraulic system. This system uses two major components. The clutch pedal is attached to the clutch master cylinder and the fluid is transmitted to the slave cylinder

The C4 clutch hydraulic system is both self-bleeding and non-adjustable. Cycling the clutch pedal multiple times while on a level grade before driving will displace any trapped air pockets formed within either cylinder. If the threaded fittings of the hydraulic line between the clutch master and slave cylinder are tight there are only three places where air can enter into the slave cylinder assembly: The slave cylinder seal, the master cylinder seal or the fluid reservoir inlet.

Both the master and slave cylinder assemblies are horizontally mounted. The master cylinder assembly faces forward and the slave cylinder assembly faces rearward. When the vehicle is parked facing uphill, the clutch hydraulic master cylinder is more likely to develop an air pocket. When the vehicle is parked facing downhill, the clutch actuator cylinder is more likely to develop an air pocket.

A Simple Test

There’s a fairly simple test to check out your clutch hydraulic system. The first step is to make sure that you’ve bled the hydraulic system and use GM hydraulic clutch fluid (P/M 12345347). When you’re convinced that you’ve done a good job and all the air is out of the system you need to do the following things to check the master and slave cylinder for leak down, or internal leaks.

- Simulate being parked on an incline by placing jack stands under the front of the car for 12-24 hours. Raise the front at least 1 foot higher than the rear.

- Lower the car being careful not to depress the clutch

- With the clutch pedal to the floor start the vehicle.

- Try to put it into reverse when it first gets started.

- If you have difficulty getting into reverse there’s a very good chance that the clutch master cylinder is not at 100%.

The following day you need to follow the same procedure but with the rear of your Corvette raised. This is the leak down test for the slave cylinder.

What happens is the hydraulic cylinders develop a leak and no pressure is available to actuate the clutch. The first thing you need to realize is that you can’t rebuild these units. Even though there are rebuild kits available for both cylinders it simply isn’t worth the effort.

When a master or slave cylinder goes bad it’s because of wear in the bore. The anodizing wears out and leaves a rough spot in the bore. That spot accelerates the wear on the rubber O-ring. You can hone the cylinder out, but when you do that you’ll enlarge the size of the bore. The O-ring seals only come in standard sizes. This means that after rebuilding the unit will fail again in a very short time because the seal will not be able to seal the enlarged bore.

The other thing to remember is that you’ve got two units and both are used every time you push down on the clutch pedal. If one of the units fails the other one is going fail also. The best idea is to replace both units at the same time. This means you only have to do the job once. This is an especially good idea since bleeding the system can be aggravating.

Don’t hesitate to replace the slave cylinder if it doesn’t bleed properly. Some people have found that they need to replace the clutch master hydraulic cylinder once for every 2 slave cylinder replacements. The hydraulic clutch system should always operate in the 97+% efficiency range to provide for normal transmission life expectancy, which is normally 75,000 – 150,000 miles.

The first thing you want to do is get the car as high up on four jack stands as you can. Is this beginning to sound familiar? You’re going to go under the car to replace the master and slave units. You’ll be under it again to bleed the system.

On the later cars you’ll have to move the computer unit out of the way in order to access the clutch master cylinder. The good part is that everything will come apart easily. Start at the top and use your flare nut wrench to break the hydraulic lines loose. Don’t remove it yet, just make sure they can be loosened It’s easier to do this before you start to unbolt the actual cylinders.

Now comes the hard part. You have to release the clutch hydraulic master cylinder linkage. This has to be done from inside the car, from under the dash. If you have the car up on jack stands and the hush panel ( this is the panel that is above the pedals and acts as a sound deadener) removed, the clip can be accessed from directly below. You can see this clip by looking through the hood release handle with a flash light.

It’s not that bad of a job as long as you have a long regular screwdriver and extra long needle nose pliers. The trick is to have the vehicle up on jack stands. That way you can sit on the floor and have your eye level be at the lower door jam level.

Bleeding the Clutch Hydraulic System

One method for bleeding this system is to let fluid simply run through the system until clean fluid comes out. Close the bleeder screw , climb into the car and press down on the clutch pedal about fifty times. Then go back under the car and allow a little more fluid out one last time.

The best bleeding process is still the conventional method where one person actuates the clutch pedal while another opens and closes the bleeder after the pedal is depressed to the floor and before the pedal is let back up. .

After the bleeding process is complete, fill the reservoir to 1/16″ below the “Low” mark so that when the “clean and dry” moisture barrier is re-inserted and lid screwed on, the fluid level remains between the LOW and HI mark. This provides the best level of atmospheric pressure isolation within the hydraulic system.

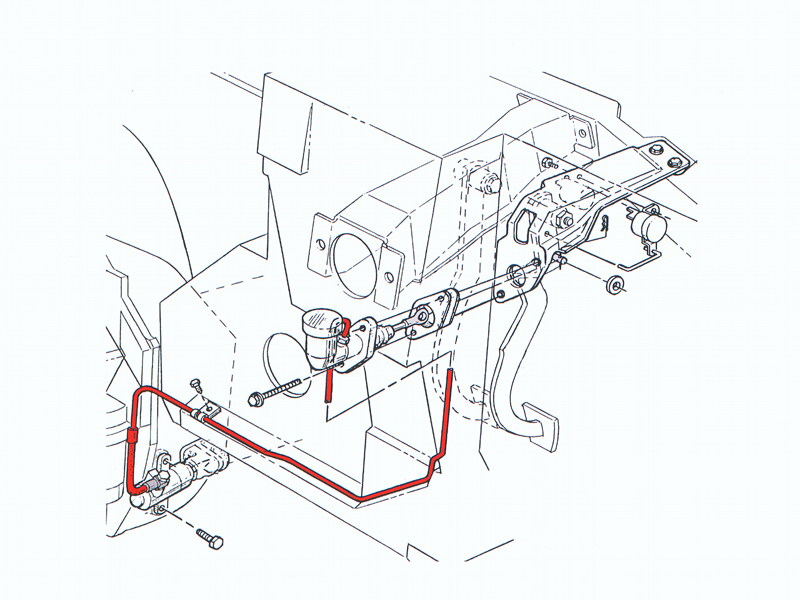

9-1.tif: The most difficult part of working on the clutch system is getting under the dash to release the small clevis pin that holds the clutch master cylinder actuating rod to the clutch pedal. This job goes a lot quicker if you have the car up on four jackstands. You don’t have to twist around quite so much to access the pin. Since the car will have to be on jackstands anyway for the bleeding process, start this project right off by getting it up in the air.

9-1.tif: The most difficult part of working on the clutch system is getting under the dash to release the small clevis pin that holds the clutch master cylinder actuating rod to the clutch pedal. This job goes a lot quicker if you have the car up on four jackstands. You don’t have to twist around quite so much to access the pin. Since the car will have to be on jackstands anyway for the bleeding process, start this project right off by getting it up in the air.

This is an adaptation from Richard Newton’s most recent book 101 Projects for Your Corvette 1984 – 1996. He has also written two other best selling Corvette One deals with the 1968 to 1982 Corvettes, How to Restore and Modify Your Corvette 1968-82 , while another deals with the Sting Rays from 1963 to 1967, Corvette Restoration Guide 1963-1967 All of these books are available from Corvette Central.

Thanks for info .

Learned something.

I am having a problem bleeding a 1985 Vette with the 4+3 Doug Nash trans. I hold the pedal and my brother opens the bleeder,the pedal goes to the floor but then when I push down again to test it, it doesn’t go all the way to the floor. It has another 2 inches at least to go and the clutch isn’t releasing. Also, I need to line up the shifter inside and I heard I may have to remove the seat and console to line them up. What do I need to line them up? Is there a tool?

I have an 86 C-4 4+3 and I cant push the clutch down all of a sudden, it worked fine a couple of weeks ago. Can you explain why. I cant move it at all. Thank you for any help.

If the problem is that you cannot release the clutch by pushing the pedal it is likely the clutch master cylinder.

If the pedal cannot move AT ALL, I do not have a suggestion for that problem.

Thank You,

Product Assistance

I had something really strange happen last year on a hot day. Lost my clutch and my rear brakes locked up and at times brakes felt like were not disengaging. I figured it was the brake booster but not sure why simultaneously i would also loose my clutch. My brakes locked up in front of my house and would not disengage until i jumped the clutch a few times to get it to move out of the road. I am going to change the vacuum line since i see it has a fuel line run to the brake booster. The car also has an aftermarket Ram hydraulic throwout bearing as well. Any thoughts?

same thing happened to my 88 while in a Trump motorcade . Lost the clutch peddle ,had it towed, 2 days later it was fine. Something about a hot master being so close to the heat shield. changed both cylinders anyway.

On my 1988 Corvette, shifting was hard or impossible. The clutch, flywheel and hydraulics were all replaced. Then it shifted perfectly but the clutch slips so badly that the car is not drivable. What do you think is the cause?

Hi, can you recommend a good transmission shop in Palm Beach Or Broward County Florida?

My 1996 LT4 seems to have clutch fluid but I can’t get it to engage into any gear. Thanks

Hi – I have a 1986 Corvette 4+3 which was difficult or impossible to shift when hot & much better but not smooth at nominal temps. I had the Clutch master, slave and connector tube replaced as fluid was filthy & parts seemed likely to be original. After installation & bleeding the difficult / impossible shifting is all the time. This is depressing & much worse than before replacing anything. In addition the OD button worked only the first time I tried and does not engage OD at all now. I returned to the Vette to shop for rechecks / rebleeding & look for OD drive switch connection at transmission. Does any of this sound familiar to you? Any & all tips / advice would be appreciated.

Thanks, Jon

That sounds heat related.

Has the shop checked lubrication levels in both the transmission and the overdrive?

Gus Gustafson

Product Assistance

Corvette Central

800 345-4122

The corvette was not temp hot in the post clutch master & slave install described previously. A second bleeding improved the shifting but still not great, Reverse, first and second gears are the worst offenders. May need to bleed yet a third time. The current reverse gear shifting grinds as if no clutch is being used. The other gears do not grind like reverse. Third & fourth seem ok, and unremarkable, Gear oil & OD dextron all topped off. The Dextron was quite dark and I will to change it.

I played around with the OD button on the shifter & sprayed some aerosol lithium grease under the button & around & under the tiny T topped rod. Is the T topped rod a mechanical connection to a solenoid switch which engages / disengages the OD?

Thanks for any and all tips on these issues.

Does anyone make Stainless Steel Sleeves for this problem?

~Sadly, the problem is with the “GM Bean-counters” for not having used stainless-steel sleeves in both Hyd.-cylinders, –would have thus been a non-issue..!!!

I’m having the same problem as Perry A. When cold all is well and then my clutch won’t disengage when hot. Still trying to figure this out…

From what I can find, this almost always points to a master or slave cylinder leak (or the line between them). The first step is to check the fluid, then bleed the system. If the problem persists, It is always best to replace both components at the same time, while you have everything apart. There is a good article on replacement on the Super Chevy website in the following link. http://www.superchevy.com/how-to/84759/

Where is the clutch cylinder reservoir on a 96 corvette?

Well, I just spent about 20 minutes looking for mine in my ’93. There is a black box, right above the battery on the driver side, by the firewall. If you contort yourself and peek under that black box you should see a white plastic bottle with a black cap. It is inaccessible with that control box in place. This is assuming the ’96 is similar, which I believe they are. Hope that helps.

My best reply is to follow the instructions in 101 Projects for Your Corvette 1984–1996.

The 1984 C4 is so difficult to shift. Maybe it’s just mine. The clutch cylinder seems to lose fluid if I allow it to sit for a while. It’s difficult to pump the clutch while driving. After pumping the Clutch it works better. Maybe it’s the slave cylinder that’s the problem. I can’t figure this out.

I would recommend taking the car to a certified Corvette technician.

I’m having the same problem with my 88 C4, changed the master and slave cylinder (new), car drives for a bit then clutch won’t disengage, pumping the clutch helps but not the solution. Wondering if you got the problem fix and if so, if you share the solution.

I have an 85 vette that I have just recently had the clutch system completely redone on. For some reason I can’t seem to find someone to do it right! I live in the Erie PA area and was just wondering if there is anyone in my area that you can recommend to possibly help me out. I took it to a vette shop and after $1400 he couldn’t get it right. His answer was that he hates working on these 1985 POS! So I’m at a crossroads and don’t know what to do here so anything you can advise would be helpful.

Unfortunately we don’t have a recommendation for that area. Best bet is to find someone with prior experience and also print off our Tech Article above to help the installer.