Pictured above on the right is Corvette Central’s Made in USA C1 battery tray (part #171301), along with a black coated tray that is a foreign made copy. The black tray is a good reproduction, as well as an option if your top priority is saving $20. However, readers should be aware that the black coating, known as “e-coating”, is not recommended by most professionals (including our own e-coater) as a “weld-through primer”. In short, there are health risks associated with welding fumes. To avoid this issue, it is recommended that the e-coating be blasted or ground back in the weld areas. If your intention is to burn off the coating by welding, make sure the resulting fumes are directed away from you in a well-ventilated area.

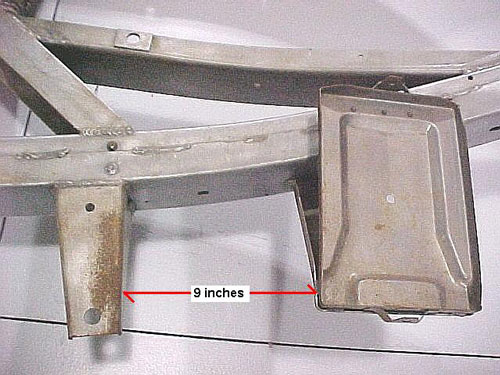

You will notice that our tray has a plain finish. It has simply been treated with a phosphate and oil (phos and oil, P&O) anti-corrosion coating. For best results, wash the oil off with a detergent and weld. The phosphate coating improves paint adhesion and is much safer to weld. Pictured below is our battery tray, mounted correctly on the frame, prior to priming and painting.

good tech guys thanks