What is your first impression upon seeing all these carburetors in a row? Sheer terror or wondering why they would do something that crazy? A few of us actually must have them. When the carburetors are set up properly, the feeling of an additional four barrels opening is exhilarating. The acceleration rate is similar in a Corvette with a supercharger or nitrous.

The trick is keeping clean fuel in three carburetors on a vehicle that is rarely driven. Depending on the length of time between run intervals, fuel tends to evaporate. In some climates, light solvents will distill out, leaving a gooey mess. Water condenses in empty or low tanks, so check before adding any fuel.

All tri-power cars have tanks that allow visual inspection of fuel quality. Before you start any tuning or troubleshooting, make sure the fuel is still volatile; it shouldn’t smell like varnish. Check for water at the bottom of the tank with a flashlight. You can usually see water as the car is pushed side to side. Water puddles in the tank ribs and looks like bubbles moving across the bottom.

While checking the tank, inspect the strainer (CC# 362209) pushed onto the fuel-sending unit’s 3/8 suction tube. If you have an original strainer, it is most likely disintegrating and dispersing particles through the fuel system, filling the filter with junk. Be sure to inspect your gas tank meter gasket too (CC# 362207).

Installing a 3/8 in-line fuel filter before the fuel pump is a great idea. Fuel pump check valves don’t like debris passing through them. The check valves will hang open and the fuel pump will stop working. Since the top of the Corvette fuel tank is the same level as the carburetor the engine will run decent at low speed and idle even when the fuel pump is not working.

It’s a good idea to add octane additives (CC# 351094) for better performance and low speed throttle response. If you have an original engine with soft valve seats, you should also use a lead additive. It’s common to find excessive fuel in the crankcase, so check the oil for fuel loading. Oil dilution will wash the rings of lubrication and cause extreme wear that’s dangerous. Holding a match to the dipstick after pulling it out will tell the tale. If the match lights the oil, fuel dilution is excessive.

Trying to avoid fuel leaks with all the lines and fittings can cause severe anxiety. We apply Teflon tape to the lines at the fitting area. This allows tightening the fittings against the lines with minimal line movement. Care must be taken to keep the Teflon tape out of the carburetor. Don’t put any tape on the seat portion of the line at all.

Trying to avoid fuel leaks with all the lines and fittings can cause severe anxiety. We apply Teflon tape to the lines at the fitting area. This allows tightening the fittings against the lines with minimal line movement. Care must be taken to keep the Teflon tape out of the carburetor. Don’t put any tape on the seat portion of the line at all.

While checking fuel and oil condition, check the hoses. Fuel hoses dry out and crack, eventually causing leaks. Hoses can also crack internally to allow rubber particles to course throughout the system. Rubber particles cause erratic carburetor fuel bowl levels and unexplained flooding. These particles stick to the needle and seat, allowing fuel to flow uncontrolled into the bowl.

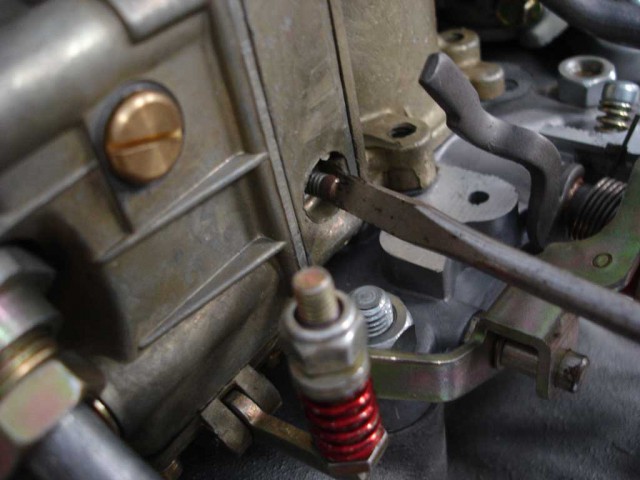

With the engine running the fuel level at each carburetor should be adjusted. Remove the fuel level sight plug and rock the car to see if any fuel spills out. Fuel should be at the bottom of the sight plug threads. It’s a good idea to have a rag under the carburetor bowl to soak up the excessive fuel. If the fuel runs out immediately the float level is too high. Be careful when adjusting the float level because fuel will spray out of the adjuster nut and screw.

With the engine running the fuel level at each carburetor should be adjusted. Remove the fuel level sight plug and rock the car to see if any fuel spills out. Fuel should be at the bottom of the sight plug threads. It’s a good idea to have a rag under the carburetor bowl to soak up the excessive fuel. If the fuel runs out immediately the float level is too high. Be careful when adjusting the float level because fuel will spray out of the adjuster nut and screw.

The next step is to ensure correct fuel pressure before condemning the carburetor or adjustments. Low fuel pressure causes hesitation and “sag” under acceleration. It is most noticeable in high gear under heavy loads. High fuel pressure can occur if the fuel return line is crimped or full of debris. Carburetor flooding and uncontrollable, overly-rich fuel conditions will result.

With the engine idling there should be no fuel visible in the venturi booster area. Carburetor idle circuit fuel is metered to the engine below the throttle plates. If you see any white smoke billowing out of the carburetor with the engine off there is an internal fuel leak.

With the engine idling there should be no fuel visible in the venturi booster area. Carburetor idle circuit fuel is metered to the engine below the throttle plates. If you see any white smoke billowing out of the carburetor with the engine off there is an internal fuel leak.

It’s common to find incorrect hoses at the fuel pump. Use only the O.E. style hoses (CC# 352353) to avoid fuel hose crimping. The close proximity of the lines to the pump will not allow universal fuel hose usage.

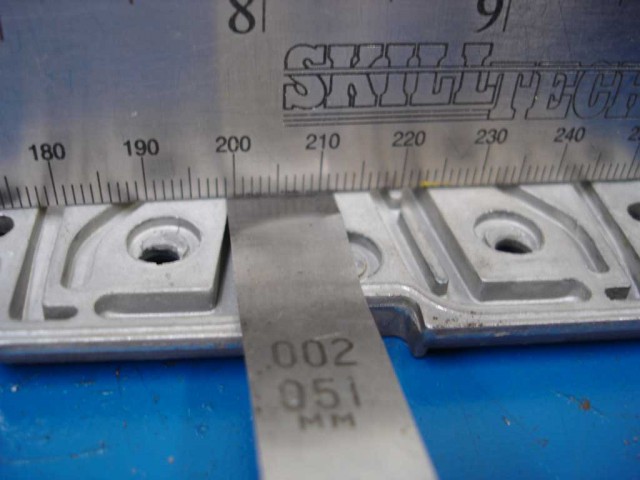

If you find an internal fuel leak on the outer carburetors check the metering plate for warping. We’ve found many warped metering plates along with corroded carburetor main bodies due to water in the fuel supply. If the carburetor main body has corrosion it most likely will require replacement.

If you find an internal fuel leak on the outer carburetors check the metering plate for warping. We’ve found many warped metering plates along with corroded carburetor main bodies due to water in the fuel supply. If the carburetor main body has corrosion it most likely will require replacement.

Many cars exhibit poor running conditions because the fuel filter (CC# 351293) is full of debris. Although it is often last checked, it is one of the easiest. You would be surprised how many particles will pass through the O.E. fuel filter. Tap on the fuel inlet side of the filter to see how many particles come out. If you find a lot of debris coming out of the filter, it is a good idea to find the source.

Lay a straight edge across the metering plate. If the plate allows you to slide a .005 feeler gauge between the plate and straight edge you’ve got problems. In some cases the metering plate can be filed flat. Consider a replacement metering plate if the warping is severe.

Lay a straight edge across the metering plate. If the plate allows you to slide a .005 feeler gauge between the plate and straight edge you’ve got problems. In some cases the metering plate can be filed flat. Consider a replacement metering plate if the warping is severe.

Here are a few tips that pertain to all Holley carburetors. Finding the fuel/air mixture needles adjusted correctly is rare. The needles are always adjusted too many turns counterclockwise (too rich). Usually, one to two turns of the needles out from their seat is the maximum number necessary. There is a balancing act between idle speed and fuel mixture; in most cases the fuel mixture and idle require small adjustments to obtain the correct setting.

Once the engine idle speed is below 1,000 RPM the fuel/air mixture needles can be adjusted. Turning the needles clockwise should slow the engine down and shut the engine off. An internal fuel leak is occurring if turning the needles into their seat doesn’t shut the engine off. Turning the needles counter-clockwise richens the idle mixture. The needles should be turned in until the engine speed drops, and then backed out slightly.

Once the engine idle speed is below 1,000 RPM the fuel/air mixture needles can be adjusted. Turning the needles clockwise should slow the engine down and shut the engine off. An internal fuel leak is occurring if turning the needles into their seat doesn’t shut the engine off. Turning the needles counter-clockwise richens the idle mixture. The needles should be turned in until the engine speed drops, and then backed out slightly.

Adjusting the fuel mixture needles too rich causes excessive fuel consumption and lazy low speed performance. Spark plugs are fuel-fouled from all that extra fuel. Adjusting the fuel mixture needles lean causes stalling and rough idle. Keep in mind, the 435 horsepower cam is not going to idle smooth but it should have a rolling idle.

Once the idle speed is adjusted the throttle linkage should be adjusted so that the throttle plates are fully closed at the outer carburetors. The throttle should be opened fully and closed with the engine off to make sure the linkage doesn’t bind.

Once the idle speed is adjusted the throttle linkage should be adjusted so that the throttle plates are fully closed at the outer carburetors. The throttle should be opened fully and closed with the engine off to make sure the linkage doesn’t bind.

To sum things up, we need clean, volatile fuel and adequate fuel pressure before making any adjustments. If the carburetor is working correctly, worst case scenario would be to start all over by turning the fuel mixture screws into their seat and then backing them out two turns and readjusting. Remember to make small changes and see what changes occur. Record the adjustments in case you need to refer to them later.

Related Items

- 152206 … 3×2 Carburetor Gasket Set

- 352063 … 3×2 Carburetor Gasket (Base to Intake)

- 352148/352085 … Carburetor Rebuild Kits

- 352135/353076 … 3×2 Carburetor Linkage

3×2 Tri-Power Corvette Carburetor/Intake Manifold Part Number & Applications

| HOLLEY CARBURETORS | ||||

|---|---|---|---|---|

| (1967) | ||||

| 400 | 4-spd ctr | 2300C | R3660A | 3902355 |

| frt/rr | 2300 | R3659A | 3902353 | |

| 400 | auto ctr | 2300C | R3888A | 3909872 |

| frt/rr | 2300 | R3659A | 3902353 | |

| 435 | all ctr | 2300C | R3660A | 3902355 |

| frt/rr | 2300 | R3659A | 3902353 | |

| (1968) | ||||

| 400 | 4-spd ctr | 2300C | R4055A | 3925517 |

| 2300C | R4055-1A | 3940929 | ||

| frt/rr | 2300 | R3659A | 3902353 | |

| 400 | auto ctr | 2300C | R4056A | 3902516 |

| 2300C | R4056-1A | 3940930 | ||

| frt/rr | 2300 | R3659A | 3902353 | |

| 435 | all ctr | 2300C | R4055A | 3925517 |

| 2300C | R4055-1A | 3940929 | ||

| frt/rr | 2300 | R3659A | 3902353 | |

| (1969) | ||||

| 400 | 4-spd ctr | 2300C | R4055-1A | 3940929 |

| frt/rr | 2300 | R3659A | 3902353 | |

| 400 | auto ctr | 2300C | R4056-1A | 3940930 |

| frt/rr | 2300 | R3659A | 3902353 | |

| 435 | all ctr | 2300C | R4055-1A | 3940929 |

| frt/rr | 2300 | R3659A | 3902353 | |

| ALUMINUM INTAKE MANIFOLDS | |

|---|---|

| (1967) | |

| 400 hp 427 engine | 3894382 |

| 435 hp 427 engine | 3894374 |

| (1968) | |

| early 400 hp 427 engine | 3919850 |

| late 400 hp 427 engine | 3937795 |

| early 435 hp 427 engine | 3919852 |

| late 435 hp 427 engine | 3937797 |

| (1969) | |

| 400 hp 427 engine | 3937795 |

| 435 hp 427 engine | 3937797 |

| 435 hp & ZL1 427 engine | 3933198 |

Story and photos courtesy Chris Petris

thank you for the information

Does anyone know of a carb repair mechanic in San Diego that can work on my tri power?

All American Carburetors is in Florida, but they do full concourse level restorations and you can ship to them.

Hi. Can you help please.. I have a 67 corvette tri power set up I bought the carbs and manifold but missing fuel line and linkage kit. Can you supply or send me in the right direction please

We offer a linkage set for 67 tri-power carburetors, our part #352135. Here’s a link to our 67 fuel lines-

https://https://www.corvettecentral.com/search?CurrentSearchCategoryId=&q=67+fuel+line&count=18

Try Corvette Clinic San Jose, they stock them.

Where does the signal come from to open the secondaries? I know that the center carb supplies the initial vacuum to open the secondaries but does most of the signal come from the primary carb? For some reason , I am not getting a strong enough signal from the center carb to open the secondaries. Any suggestion what to look at on the center carb? Air bleed stopped up? What is a good vacuum number to look for on the center carb tap for this common line to the secondary diaphragms?

Look here:

https://www.ebay.com/itm/363600880710?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=363600880710&targetid=1262749490862&device=c&mktype=&googleloc=9017352&poi=&campaignid=14859008593&mkgroupid=130497710760&rlsatarget=pla-1262749490862&abcId=9300678&merchantid=8026134&gclid=Cj0KCQjww4OMBhCUARIsAILndv59IRlHiwgKQoy3aIaZ8e-NhJ1zKtCi7vYTYo5q8eAgi2K1GRtq7IQaAjBpEALw_wcB

Regards,

Gus

Corvette Central Product Assistance

After a close inspection of this tri power I picked up for my 69 corvette I found the front carb to have a metering block in it instead of a metering plate the block has air adjustment screws and the jets are 76 which is correct and the block is not made to accommodate a power valve is this a trick modification ? and how do you adjust it or should I change it back to a metering plate it also has 1/4 inch spacer plates under the carbs .

I have a 1969 Corvette with a 427 that now has a large cap HEI ign. with tach drive will a factory tri power work with this set up or will I need to convert back to a small cap ign.

Need the factory jet sizes in the three cards and also the factory power valve to get this 67 435 HP back to a good starting point (too many shade tree mechanics have worked on this one).

So do you leave the 2 outside carbs mixture screw screwed in

There is not any adjustment screws on the front and rear carb

In regard to the post about turning in the idle screws and the car not shutting off it sounds like a power valve issue. If the power valve is blown or has too high vacuum number that will dump gas into the carb and it won’t shut off. Take the engines warm idle vacuum reading. In gear if automatic. Divide that reading in half and get the power valve corresponding to that number. If the car still won’t shut down you shutoff linkage May need adjustment. The first and third carburetor do weep a small amount of gas at idle. This is done to keep the gas in fuel bowls 1 and 3 fresh. It is factory set. If you have an exotic cam you may need a lower power valve to keep it closed with rough ideling.

How is the manual linkage adjusted connecting the primary carb to the outer carbs? Is the nut tightened on the slot of the primary carb so all three butterflies open at the same time?

The mechanical linkage between the 3 carburetors is a one-way linkage to insure positive closing of both end carburetors when the accelerator is released. To adjust: With engine off, move dash lever fully rearward against dash panel. Adjust throttle rod by turning rod in swivel to line throttle rod up with carburetor lever hole. No binding should occur between accelerator rod and carburetor lever.

The end carbs comes in by vacuum , the linkage is to make sure the end carbs kicked off when you let off the gas , the nut has to be loose so the linkage can slip . If all three carbs come in at once your engine will boog down , there is no accelerator pump on the end carbs .

I installed 3 new holley carbs on my 427, it has alu. heads and 11 to 1 compress. The intake is 3919852. Runs like an internal fuel leak or vac leak, revs up fine but slow coming down. When adjusting the fuel/air mix screws it will not shut off motor. Also the lever on the rear throttle shaft drags on the intake manifold.

We recommend you take the car to a certified Corvette technician.

Probably the most important factor in getting 3×2 carbs to work right is vacuum and the strength of the springs in the vacuum secondaries. Wrong spring or bad vacuum=bad performance and a big bog. Remember the vacuum also runs the headlights and wiper door. Any leaks in these systems can affect overall performance. The secondary vacuum springs are related to load under acceleration, they have to work in unison for the system to work properly. Lighter springs open sooner. If they open too soon you get a glut of gas and a bog. If they open too late you will lose low rpm speed. Physically testing of secondary openings is needed to get optimum performance from these or any vacuum secondary 4bbl Holly. Putting a small screw in the secondary shut down linkage is a fool’s way of getting the secondaries to open. Performance suffers.

Where do you get lighter springs?

From Holley. They sell kits with different weights of springs.

Also weigh the floats from the end carbs and if they weigh more than 10 grams, they are absorbing gasoline and need to be replaced.